Hot tubs

What is a hot tub?

The product standard for hot tubs is IEC 60335-2-60:2017 Safety of household and similar electrical appliances, particular requirements for whirlpool baths and whirlpool spas. In this standard hot tubs are called ‘whirlpool spas’, the definitions from the standard are provided below:

Whirlpool bath

Appliance used by persons to immerse themselves in water and which incorporates provisions for blowing air or water circulation and which may have provisions for water heating, the appliance intended to be drained after use.

Whirlpool spa

Appliance used by one or more persons at the same time to immerse themselves in water and which incorporates provisions for blowing air or water circulation and provisions for water heating, the appliance not intended to be drained after use.

The main difference between a bath and a spa is the latter is intended to be used by one or more persons and it is drained after use, neither of which is much help for the electrical designer.

How many hot tubs are sold each year in the UK?

There has been a surge in sales of hot tubs in the UK recently, it is understood that there are approximately 2,500 swimming pools, 25,000 hot tubs and 250,000 portable hot tubs sold each year in the UK. To put this into perspective, these numbers are similar to the numbers of electric vehicle sales from 2016.

Hot tub construction

Hot tubs come in many different forms from soft inflatable to a more permanent hard-shell construction. Inflatable hot tubs are usually sold as ‘plug and play’ and, the theory is, they do not need to involve an electrician for installation but that is another issue and not covered in this article.

Hard-shell hot tubs are typically class I appliances due to their construction and require a protective earth connection. One of the reasons for this is being the water heating element is immersed in the water.

Whilst it could be argued that a hot tub has insulated panels which prevent access to any metal parts, however, the exposed-conductive-part in this case is the water. The electrical conductivity of the water is increased by chemicals or minerals that are added for sanitization.

What are the risks to persons using a hot tub?

The risk of electric shock is increased when a person is wet due to the decreased body resistance which allows an increase in current through the body in the event of contact with live parts. This risk is further increased when a person is using a hot tub outdoors due to the possibility of contact with Earth. Which is exactly the same risk as for a person using a swimming pool.

What does the product standard say?

The product standards are there to ensure safety of the product but do not take account of the local installation, which is a task for the electrical designer. BS EN 60335-2-60 requires manufacturer’s instructions to refer to National Wiring Regulations, in the UK this is BS 7671:2018+A1:2020.

What are the requirements for hot tubs in BS 7671:2018+A1:2020?

Hot tubs are not specifically defined in BS 7671:2018+A1:2020, therefore, the designer must consider the risks and make an engineering judgement to select the most appropriate protective measures. Deciding on the required protective measures to apply will depend on the location of the installation and the associated risks.

Indoors

If a hot tub is installed indoors, the risk is a person is or has been immersed in water, therefore their body resistance is reduced. Section 701 applies to locations containing a bath or shower and the surrounding zones and would be applicable to a hot tub installed indoors.

Outdoors

In the UK, it is probably more likely for a hot tub to be installed outdoors. The risks associated with an outdoor hot tub is similar to indoors with respect to reduced body resistance, but with the additional risk of barefoot contact with Earth, which significantly reduces overall resistance, and cause an increase in the body current in the event of contact with a conductive part made which has become live under normal or fault conditions.

Section 702 of BS 7671:2018+A1:2020 applies to the basins of swimming pools, fountains and paddling pools. The scope of Section 702 states that ‘in these areas, in normal use, the risk of electric shock is increased by a reduction in body resistance and contact of the body with Earth potential.’

This risk is exactly the same for a person using a hot tub, the fact that the person is wet will reduce their body resistance significantly, which combined with it being installed in a garden, increases the potential for contact with Earth.

How could an electrical designer claim as a defence that the risks of electric shock for a hot tub installed outdoors is any less than that of a swimming pool, fountain or paddling pool, as defined in the scope of Section 702?

What are the requirements of Section 702 in BS 7671:2018+A1:2020?

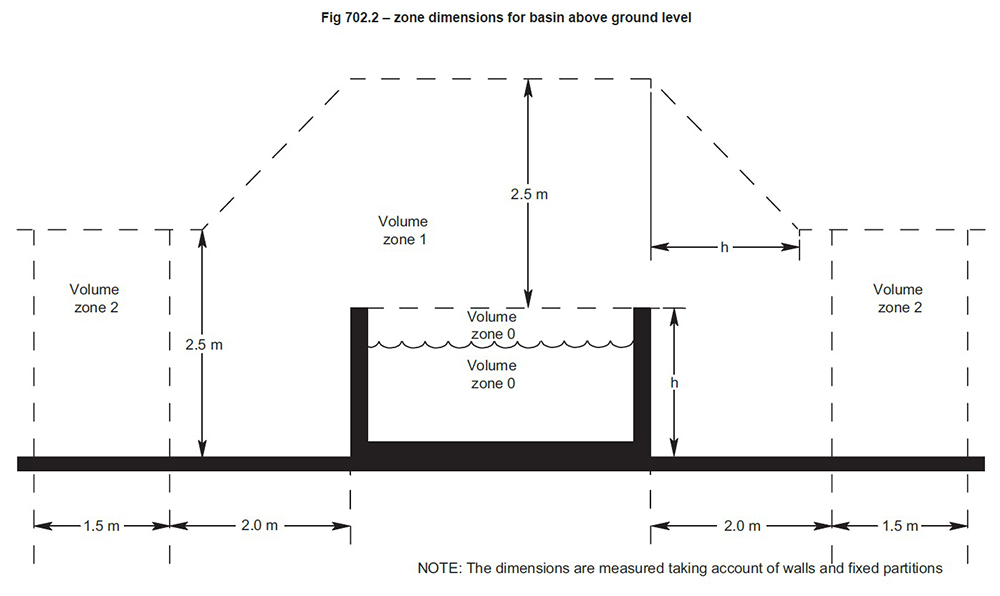

Section 702 imposes zoning requirements for the installation and surrounding areas as detailed in Figure 702.2, for basins of water above ground level. This could have implications for any exposed-conductive-parts or extraneous-conductive-parts installed in close proximity to the hot tub such as lighting or metallic structures.

For zone 0 and 1

Switchgear, accessories and junction boxes shall not be installed in zone 1, with the exception of SELV junction boxes.

The only wiring permitted in zone 0 and 1 is that necessary to supply equipment in those zones. It is preferable for cables to be installed in a conduit made of insulating (i.e. non-metallic) material.

For zone 2

Electrical equipment, socket-outlets, switches and accessories are permitted to be installed in zone 2 providing they are protected by electrical separation, SELV or a 30 mA RCD and of course suitably IP rated. Again, it is preferable for cables be installed in a conduit made of insulating material.

Any electrical equipment installed outdoors and in zone 1 or 2 requires a minimum IP rating of IPX4, or IPX5 where water jets are likely to occur for cleaning purposes.

Figure 1: Fig 702.2 - Zone dimensions for basin above ground level

Section 702 recognizes the increased risk and the following Note is included in Regulation 702.410.3.4.3.

NOTE: Where a PME earthing facility is used as the means of earthing for the electrical installation of a swimming pool or other basin, it is recommended that an earth mat or earth electrode of suitably low resistance, e.g. 20 ohms or less, be installed and connected to the supplementary protective equipotential bonding.

This is describing an earthed metallic grid installed under poolside areas and connected to the supplementary bonding as required by ENA G12/4 for swimming pools and outdoor shower locations, which is similar to the metallic grid depicted in Figure 705 of BS 7671:2018+A1:2020 for cattle sheds in agricultural locations. This protective measure is likely to be expensive and impractical for hot tub installations.

Can I install a socket-outlet for a hot tub?

Whilst the installation of a socket-outlet is not precluded in BS 7671:2018+A1:2020, socket-outlets installed in close proximity to basins of water are not generally a good idea due to the potential for misuse. In some cases, a socket-outlet could be specified by the manufacturer, in which case it is permitted to be installed in zone 2 if the protective measure automatic disconnection of supply (ADS) is applied, using an RCD specified in Regulation 415.1. In other words, an RCD with a rated residual operating current of 30 mA is installed.

Best practice is to install fixed wiring for connection of the hot tub, so as prevent misuse of a socket-outlet. An isolator should be provided and installed outside of zone 1, 2 m from the edge of the basin, as seen in Figure 1.

It is important to remember that where containment for wiring, such as conduit is used, it is preferable that it is made from insulating material i.e. non-metallic. (Regulation 702.522.21 of BS 7671:2018+A1:2020).

Can I install lights around a hot tub?

Regulation 702.55.4 provides special requirements for the installation of electrical equipment in zone 1 (2 m horizontally from edge of basin to a height of 2.5 m) of swimming pools and other basins. Whilst it is preferred to install lighting outside of zone 1, Regulation 702.55.4 states:

For swimming pools where there is no zone 2, lighting equipment supplied by other than a SELV source at 12 V AC rms or 30 V ripple-free DC may be installed in zone 1 on a wall or on a ceiling, provided that the following requirements are fulfilled:

- The circuit is protected by automatic disconnection of the supply and additional protection is provided by an RCD having the characteristics specified in Regulation 415.1.1

- The height from the floor is at least 2 m above the lower limit of zone 1.

In addition, every luminaire shall have an enclosure providing Class II or equivalent insulation and providing protection against mechanical impact of medium severity.

This means that it is not permitted to install metallic class I luminaires within 2 m of a basin. As described above, luminaires must be mounted on the wall or ceiling, not flush in the floor surrounding the basin as is frequently seen for hot tub installations.

What type of RCD is required for a hot tub?

It is important that the correct RCD is selected according to manufacturer’s instructions. The correct type of RCD required will depend on the type of electronic circuits used within the product. Different electronic circuits are used for functions such as speed control of pumps which may dictate a particular type of RCD.

Residual DC leakage current can cause blinding of AC and other type RCDs depending on the amount of leakage current, but that is another story, see IET Wiring Matters ‘Which RCD?’ article for further information. If an RCD with resilience to DC leakage is required, such as a type A, it is important to ensure any RCDs upstream of this device are also selected to prevent blinding by DC residual current.

IET guidance

Chapter 13.8 of IET Guidance Note 7 Special Locations states that where a hot tub is installed indoors, the requirements of Section 701 should be applied and where it is installed outdoors, it is recommended that the requirements of Section 702 should be applied in full.

Chapter 14 of IET Guidance Note 5 provides information on PME earthing arrangements with respect to wet locations where persons may be barefoot. In addition to normal electric shock hazards, persons may experience low-level shocks or tingles from the out-of-balance voltages imported via the neutral/earth conductor of the DNO TN-C-S system when in barefoot contact with Earth.

Can I connect a hot tub to a PME earthing arrangement?

BS 7671:2018+A1:2020 does not preclude connecting a hot tub to a PME earthing arrangement. However, when the facts are examined it is easy to see why it may not be considered appropriate.

Let’s take a look at the risks associated with PME earthing arrangements and wet locations such as swimming pools. Usually when we mention the dreaded abbreviation PME, we are considering loss of the PEN conductor. However, with swimming pools and similar wet locations where persons can access barefoot, problems can exist under normal operating conditions.

IET Guidance Note 5 Protection against electric shock, provides guidance on perceived electric shock. Perceived electric shock may be experienced on PME earthing arrangements under normal operating conditions due to a potential difference which may exist between the PEN conductor and Earth.

This can occur if an installation is supplied from a long distribution and/or service cable. Depending on the load on the circuit and the ratio of the load on the network, a potential difference could exist between the PME earthing terminal and Earth. Whilst it may only be a few volts, in combination with reduced body resistance, due to wet skin, and the additional possibility of contact with Earth, it can be enough to cause a ‘perceived electric shock’.

If the designer chooses not to use the PME earthing arrangement and decides to install a TT earthing system, special care must be taken to avoid simultaneous contact between accessible metallic parts connected to different earthing arrangements, see Regulation 411.3.1.1 of BS 7671:2018+A1:2020. In some cases, it may be necessary to install a TT earthing system for the whole installation to prevent the risk of contact with metallic parts at different potentials.

What are the voltages that can be expected between the Protective Earthed Neutral (PEN) conductor and Earth?

For this we need Ohm’s Law, the prospective touch voltage (Utp) is limited by the product of neutral current x PEN conductor resistance.

For a supply in accordance with Electricity Safety, Quality and Continuity Regulations (ESQCR) 2002 (as amended), i.e. 230 V +10%/-6%, the upper limit for prospective touch voltage between PME and Earth is 18.4 V. Let me explain, the maximum volt drop permissible on the LV network is 253 V – 216.2 V which is 36.8 V. If we assume that half of the voltage drop is in the line conductor and half in the PEN conductor equates to 36.8/2 which is 18.4 V.

It is important to remember that this is prospective touch voltage, the voltage and current across the body is determined by the combined resistance of the body and additional resistances such as footwear or surface materials.

There are many factors which affect the prospective touch voltage between the Main Earthing Terminal (MET), connecting the PME earthing arrangement and Earth, such as the network impedance and the ratio of load, which will affect the magnitude of neutral current on the distribution network.

A typical 100 A supply with a line to neutral impedance of 0.1 Ω at full load current, the voltage drop on the distribution network is 10 V (100 x 0.10 = 10 V). If the impedance is 0.368 Ω, the voltage drop increases to 36.8 V (100 x 0.368 = 36.8 V).

As the line neutral impedance is increased, the potential for prospective touch voltage is also increased. It is not uncommon for the recommended values of Ze to be exceeded for some installations. Some premises may have an external impedance of up to 0.6 Ω and above, for further information see IET Wiring Matters article Earth fault loop impedance revision of ENA Engineering Recommendation P23.

Neutral current is probably the biggest factor when determining the magnitude of prospective touch voltage, which on a balanced three phase distribution network should not be an issue. However, it’s important to note that in practice a balanced three-phase system with single-phase loads connected is unlikely. It is suspected that there is a high level of imbalance across the distribution network as identified in HV and LV Phase Imbalance Assessment Report No 7640-07-D4 produced by Scottish Power Energy Networks (SPEN). Imbalance is more likely to affect networks consisting of mixed commercial and residential loads and networks in rural locations as less customers reduce load diversity.

What level of touch voltage is dangerous for a wet person?

Touch voltage thresholds are related to touch current by the body impedance and ohms law. It is a very complicated subject and is affected by many factors such as:

- AC or DC

- the magnitude of touch voltage

- the current pathway through the body

- the area of contact with the skin

- the condition of the skin contact area, and

- duration of the current flow.

The IEC 60479 series studies the effects of current on human beings and livestock. IEC TR 60479-5:2007-11 Touch voltage threshold values for physiological effects covers touch voltage threshold values.

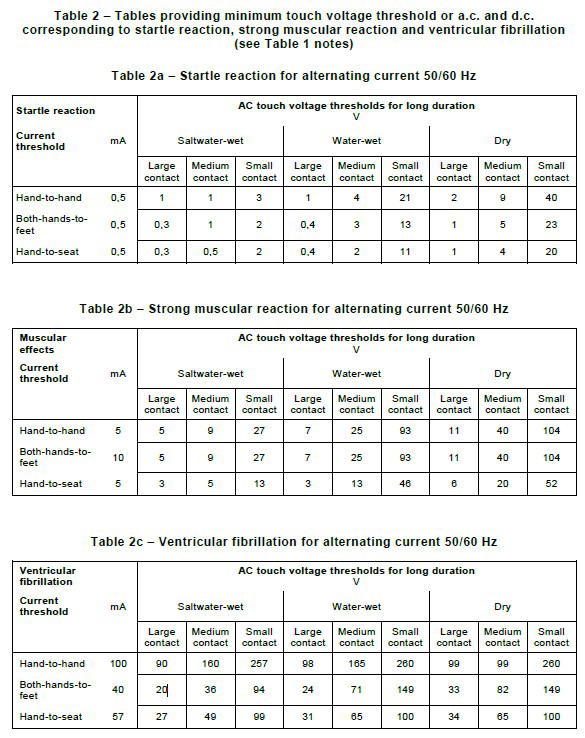

Table 1 indicates touch voltage thresholds for different conditions. IEC TR 60479-5 considers a large contact area to be a full hand contact with a surface area of 82 cm², medium contact are might represent the palm of the hand (12.5 cm²) and a small contact area might represent touching a small conductive part with the hand (1 cm²).

The environmental conditions are an important factor when determining touch voltage thresholds. Dry condition corresponds to normal indoor conditions, water-wet skin condition corresponds to skin that has been immersed for more than 1 minute in normal water and saltwater-wet skin condition is considered to be skin that has been immersed for more than 1 minute in a solution of 3 % NaCl in water (average value ρ = 0,25 Ω × m, pH = 7,5 - 8,5).

When considering the relevant conditions, it’s important to remember that additional safety margins may apply. An important factor to consider for hot tubs is the conductivity of the water, which is likely to have higher conductivity than tap water due to chemicals or minerals added for sanitisation purposes.

The report states voltage thresholds are not easily used for applications which involve immersion of body parts, Annex C Clause C.2 provides common situations and for swimming pools as below:

Water from swimming pools contains chemicals which will increase conductivity and swimmers have bare hands and bare feet. When playing, wet people may touch electrical appliances and could support for a long period a touch voltage less than 11 V a.c. which corresponds to medium contact area for inability to let-go. For swimmers immersed in a pool, the allowable touch voltage threshold will be much lower.

Figure 2: Table 2 - Tables providing minimum touch voltage threshold

What if a PEN conductor becomes open circuit?

Another concern regarding PME earthing arrangements is the risk of an open-circuit neutral PEN conductor. In this situation, all metal parts connected to the main earthing terminal (MET) could rise up to 230 V with respect to Earth, this includes the hot tub heater element which in turn is ‘connected’ by means of the water within the hot tub. The water is effectively an exposed-conductive-part with an extremely large surface area.

The current would be significantly higher under open-circuit PEN conductor conditions, in the region of amps as opposed to milliamps. It is important to remember that an RCD would not operate under open-circuit PEN conductor conditions, if a person makes contact with the water and Earth under open-circuit PEN conductor fault conditions and in bare foot contact with Earth, it is likely to have fatal consequences.

What is the likelihood of a rise in potential on the MET?

Other scenarios which could raise the potential of the main earthing terminal include:

- live to earth faults on HV network with combined HV/LV earthing (Regulation 442.2.2) (Uo+250 V >5s or Uo+1200 V <5s);

- insulation faults on final circuits within the installation

(some circuits may have a 5 second disconnection time); and

- lightning strokes.

Whilst the probability of each scenario may be considered relatively low, the probability of a rise in potential on the MET increases when they are combined.

What are the Distribution Network Operator (DNO) requirements?

Section 6.5.2 of Energy Networks Association (ENA) Engineering Recommendation G12/4 provides requirements for network operators regarding special situations such as swimming pools and other basins containing water. The safety issues highlighted are identified in the list and note below.

- Wet locations

- Possibility of contact of the body with true Earth potential

- Presence of wet barefoot persons

NOTE: in addition to normal electric shock hazards, persons may experience low level shocks or tingles from the out of balance voltages imported via the neutral/earth conductor of the DNO TN-C-S system.

ENA Engineering Recommendation G12/4 provides guidance on information to be provided to competent persons enquiring about the suitability of PME for swimming pool supplies. A TT earthing system is recommended, or alternatively PME is permitted providing a metallic grid connected to the main equipotential bonding is installed under the poolside area.

Section 6.2.6.2 of ENA Engineering Recommendation G12/4 sets out the requirements for caravan sites, campsites and amenity shower blocks.

‘Due to the higher probability of persons being barefooted at toilet and amenity shower blocks (including sports pavilions with shower facilities) the extension of PME earthing is not recommended unless a buried bonded metal grid has been installed. This requirement also applies to other locations where toilet or shower blocks have been provided for general public use where people are likely to be barefoot e.g. beachside locations, parks etc.

Where outside showers have been provided, provision of PME earthing is not recommended as providing a reliable equipotential cage may prove impractical.’

Looking at the risks outlined above it is difficult to see how the electric shock risks for hot tubs are any different. Ultimately, it is the decision of the designer whether or not to use the PME earth terminal, this is reinforced in ENA Engineering Recommendation G12/4 but it is difficult to see how it could be justified.

Roles and responsibilities

When a hot tub installation is under consideration, a conversation will be required between all interested parties, typically the client, the hot tub supplier and the electrical installer. It is essential that the roles and responsibilities are established before any work takes place.

Electrical contractors are frequently requested to provide a socket-outlet or isolator for the hot tub installer to connect to at a later stage. It is important to remember that whilst it may be acceptable to certify works for which they are responsible comply with the relevant standards, would it be considered acceptable in a court of law to ignore the facts?

Generally, hot tub installers are not qualified electricians and do not usually have sufficient knowledge of BS 7671:2018+A1:2020 to be able to make informed engineering judgements on protective measures such as earthing and zone requirements. It would be unreasonable to expect a hot tub installer to have the same level of knowledge as the electrical designer.

The client should be specifically informed that the person certifying the electrical supply point for the hot tub does not take responsibility for the design of the complete hot tub installation. If it was explained to the client clearly that the final connection could be made by a person who may not be conversant with BS 7671:2018+A1:2020 and may not have taken all risks into consideration, a different view may be taken by the client and it may be preferable for the electrician to certify the complete design.

What is the law?

The Health and Safety at Work etc Act 1974 states ‘that it shall be the duty of every employee while at work to take reasonable care for the health and safety of himself and of other persons who may be affected by his acts or omissions at work’.

Failing to provide sufficient information to the client could be seen as an omission. The electrical designer has a moral and legal obligation to discharge their duty of care and pass on their knowledge to ensure the whole installation is safe.

Summary

The increased risks associated with using a swimming pool are reduced body resistance and contact with Earth, hot tubs when installed outside are no different from swimming pools with respect to risk of electric shock. The outside protective measures apply to the hot tub and the zones surrounding the area.

The combination of potential of contact with live parts with reduced body resistance and contact with Earth can be a dangerous. Electrical installations for hot tubs require careful consideration as well as planning and should only be designed and installed by electrically skilled persons.

Whilst connecting a hot tub installation to a PME earthing arrangement is not precluded, it is difficult to see how it could be justified by the electrical designer given the information available.