Which RCD Type?

What are RCDs?

Residual Current Devices (RCDs) are safety switching devices. They are designed to provide safety for three types of protection; these are:

- Fault Protection. Any tripping current dependent on the resistance of the earth path. (Regulations 411.4.204; 411.5.1; 531.2).

- Additional Protection. RCDs not exceeding 30 mA tripping current. (415.1).

- Fire Protection. A tripping current not exceeding 300 mA. (422.3.9).

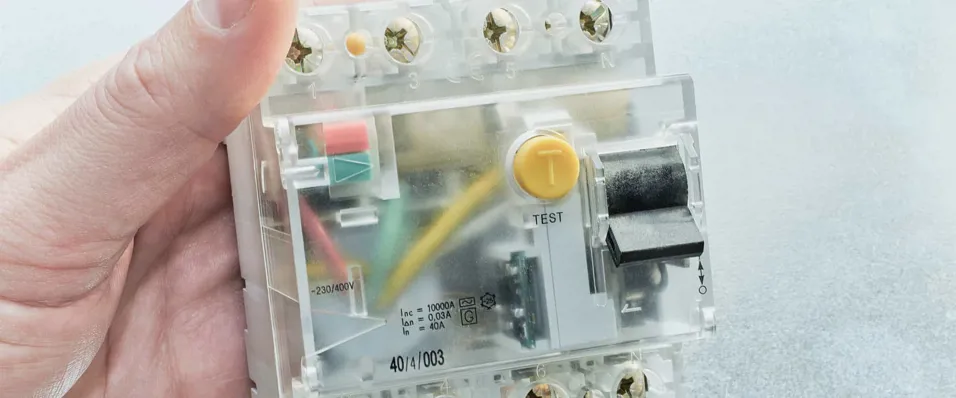

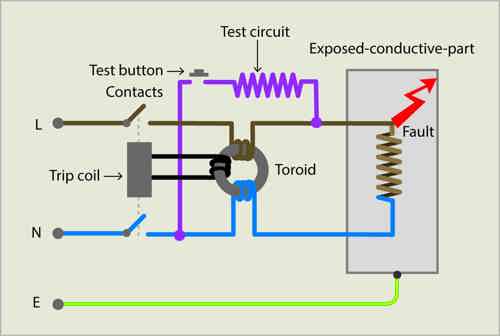

An RCD monitors the earth leakage current in a circuit. It is constructed from coils of wire wound around a ferrite toroid core, one for each live conductor of the circuit protected. When a current imbalance between live conductors is detected, a voltage will be induced in the tripping coil which will disconnect the electrical supply to the protected circuit (see Figure 1).

Figure 1 Single-phase RCD

RCDs are far more sensitive than circuit-breakers. The sensitivity being rated in milliamps (mA) as opposed to amps (A).

Different Types of RCD

Residual Current Device is a generic term used for describing devices which incorporate residual current protection in accordance with one of the standards below:

- Residual Current Circuit-Breaker (RCCB) without protection against overload BS EN 61008, BS 4293, BS EN 62423.

- Residual Current Circuit-Breaker (RCBO) with protection against overload BS EN 61009.

- Socket Outlet incorporating a Residual Current Device (SRCD) with or without overcurrent protection BS 7288.

- Portable Residual Current Device (PRCD) BS 7071.

How do RCDs work?

RCDs work by monitoring the flow of current in a circuit's live conductors and, if the flow of current is imbalanced due to an earth leakage current of a set nominal value, the device will trip to cut off the supply to the circuit. Whilst RCDs have a nominal tripping current (IΔn), they may trip below the nominal value; for instance, a 30 mA RCD is required to trip at a current between 18 mA to 28 mA.

It is important to understand that RCDs cannot limit voltage or current, they provide protection by limiting the time a specific maximum current can flow to earth.

In a healthy circuit, the vector sum of the currents flowing in all live conductors should be nominally zero. When a fault occurs on a circuit causing a current to flow to earth, this creates an imbalance and trips the device.

What is DC residual/fault current?

Some equipment will have DC leakage current by the nature of design, other equipment may produce DC currents during fault conditions, dictated by the construction of the equipment.

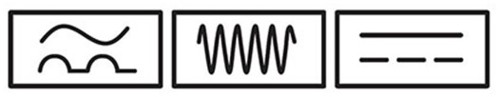

BS 7671:2018 Annex 53, Figure A53.1 provides examples of possible fault currents in systems with semiconductors. This demonstrates how the shape of the waveform is affected on various types of circuits under load and fault conditions.

What does BS 7671:2018 require?

Recently introduced in the BS 7671:2018, Regulation 531.3.3 states that different types of RCD exist and the appropriate type shall be selected according to the connected equipment.

Extract from BS 7671:2018:

“531.3.3 Types of RCD

Different types of RCD exist, depending on their behaviour in the presence of DC components and frequencies. The appropriate RCD shall be selected from the following:

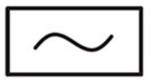

(i) RCD Type AC: RCD tripping on alternating sinusoidal residual current, suddenly applied or smoothly

increasing

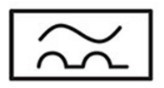

(ii) RCD Type A: RCD tripping on alternating sinusoidal residual current and on residual pulsating direct current, suddenly applied or smoothly increasing.

NOTE 1: For RCD Type A, tripping is achieved for residual pulsating direct currents superimposed on a smooth direct

current up to 6 mA.

(iii) RCD Type F: RCD for which tripping is achieved as for Type A and in addition:

(a) for composite residual currents, whether suddenly applied or slowly rising, intended for circuit supplied between line and neutral or line and earthed middle conductor

(b) for residual pulsating direct currents superimposed on smooth direct current.

NOTE 2: For RCD Type F, tripping is achieved for residual pulsating direct currents superimposed on a smooth direct

current up to 10 mA.

(iv) RCD Type B: RCD for which tripping is achieved as for Type F and in addition:

(a) for residual sinusoidal alternating currents up to 1 kHz

(b) for residual alternating currents superimposed on a smooth direct current

(c) for residual pulsating direct currents superimposed on a smooth direct current

(d) for residual pulsating rectified direct current which results from two or more phases

(e) for residual smooth direct currents, whether suddenly applied or slowly increased, independent of

polarity.

NOTE 3: For RCD Type B, tripping is achieved for residual pulsating direct currents superimposed on a smooth direct current up to 0.4 times the rated residual current (IΔn) or 10 mA, whichever is the highest value.

For general purposes, Type AC RCDs may be used.

NOTE 4: For guidance on the correct use of RCDs for household and similar use, see PD IEC/TR 62350.

NOTE 5: Some typical fault currents in circuits comprising semiconductors are given in Annex A53, Figure A53.1.”

What are the effects of DC residual fault current on RCDs?

To help explain, it might be worth thinking about some older models of earth fault loop impedance testers, which could cause the RCD to operate unintentionally. To prevent this, some types of earth fault loop impedance testers imposed a DC current on the AC test current. This DC current saturated the magnetic core of the RCD preventing it from tripping under the test condition.

Where equipment produces an element of residual DC, for example, variable-speed drives is connected to the electrical installation, the DC component can saturate the magnetic core and effectively blind or locks the RCD. This is known as 'blinding' and could either prevent the RCD from operating or reduce the sensitivity resulting in a dangerous situation.

What types of equipment have DC residual leakage current?

The advent of new technologies has created different challenges for the electrical designer and installer. Some modern equipment can create DC residual fault current. Such items include, variable-speed drives, LED lighting, washing machines, dishwashers and tumble dryers.

Solar photovoltaic systems incorporate inverters to convert DC to AC for use either within the electrical installation or to be supplied to the National Grid. Some inverters may provide galvanic or electrical separation between the AC mains supply and the DC side of the PV array. Where this is not the case, some manufacturer’s instructions state that Type B RCDs to BS EN 62423 must be used.

Where electric vehicle charging equipment is likely to create a residual DC fault current, manufacturers may provide the correct type of RCD within the charging equipment. However, problems could arise if the charging equipment is installed downstream of an existing Type AC RCD, which could be blinded by the residual DC fault current. In some types of DC charging equipment, the AC input side is galvanically isolated from the DC output which, hence, provides electrical separation. This means that faults on the DC output side, connected to the vehicle, would not be detected by an RCD on the input side of the circuit.

What are the hazards and problems?

In new installations, it is common practice to install a consumer unit which was supplied with RCDs already connected. These are likely to be Type AC which could be ineffective due to the residual DC fault current created by types of electrical equipment. Many installers, either because of habit or a misunderstanding of the limitations for an AC Type RCD, often assume they are suitable for all installations, but this is incorrect.

Some European countries have already banned the general use of Type AC RCDs and some manufacturers have stopped making them, supplying Type A in place of Type AC.

In existing electrical installations, Type AC RCDs have been installed for many years and are effective for equipment which is resistive, capacitive or inductive and fitted with minimal electronic components. This used to be the case for most installations when lighting was of the tungsten type, and the electrical appliances or equipment did not contain any electronic equipment.

Modern appliances are becoming increasingly more sophisticated, featuring microprocessor technology with an emphasis on energy reduction. This has led manufacturers to incorporate energy-saving measures, such as speed control, which by the nature of its operation has an element of DC residual fault current.

Which types of installation could be affected?

All types of electrical installations could be affected, it depends on the equipment which has been installed. Examples include:

- Domestic properties with modern equipment and appliances, such as LED lighting, induction hobs, IT equipment and electric vehicle charging equipment.

- Commercial installations comprising LED lighting and large quantities of IT equipment which can also cause other issues, such as protective conductor current which should also be considered.

- Industrial installations using uninterruptible power supplies (UPS) and variable speed drive (VSD) frequency inverters for the speed control of motors.

- It should be noted that the residual DC leakage current can vary with motor speed and cable length.

- Swimming pool installations can be at risk when equipment such as pumps are being replaced with newer equipment incorporating VSDs, without any consideration as to whether the existing Type AC RCD is still suitable for the application.

Other examples of installations which require protection by RCDs include:

- Construction sites

- Agricultural and horticultural premises

- Conducting locations with restricted movement

- Caravan and camping parks

- Exhibition shows and stands

- Outdoor lighting

- Marinas

- Medical locations

- Solar Photovoltaic system power supplies

- Mobile or transportable units

- Electric vehicle charging installations

- Temporary installations for structures, amusement devices and booths at fairgrounds, amusement parks and circuses, and

- Floor and ceiling heating systems.

How do I select the correct Type of RCD?

It is important to select the correct Type of RCD for the equipment to be used. The Type of RCD will depend on the characteristics of the equipment. Where necessary, equipment manufacturers should specify the RCD Type required. If the information is not available, the manufacturer should be contacted and asked to provide it. It is a legal requirement of UK Product Safety Regulations for manufacturers to provide clear installation instructions to enable safe installation.

If equipment contains Power Electronic Converter Systems (PECS), more commonly known as inverters or VSDs, BS 62477-1 Safety requirements for power electronic converter systems and equipment sets out the requirements and Annex H provides guidelines for RCD compatibility. Manufacturers must define the safety requirements clearly for suitable RCDs. If this information cannot be obtained, a Type B RCD should be installed to cover the worst-case scenario.

As an installer won’t be able to predict the different types of equipment that is likely to be connected to an installation during its lifetime, consultation with the client is essential in order to determine the most suitable RCD type required.

The cost of a Type A RCD is more than an AC Type and, subsequently, B and F Types are significantly more than that (currently hundreds of pounds) therefore it is important to understand the requirements or a significant amount of money could be wasted.

What are the different types of RCD?

There are many different RCD types available, each being suitable for different equipment types, as identified in Regulation 531.3.3 of BS 7671:2018.

The RCD type should not be confused with the different types of circuit-breakers which are manufactured according to their time/current characteristics. Circuit-breakers for overcurrent protection of cables are available in types B, C and D in accordance with BSEN 60898-1. It's quite easy to see how an RCBO with a B Type time-current curve could be mistaken for a Type B RCD.

Selectivity (Discrimination)

In the 18th Edition, the term for discrimination has been changed to selectivity. It is important to achieve selectivity when installing multiple RCDs in series. A common misconception is that an RCD with a higher mA sensitivity rating will provide selectivity, but this is not the case due to the instantaneous operation of the device. The only way to achieve selectivity with RCDs is to install a time-delayed device upstream.

Type S (Time-delayed)

A Type S RCD is a sinusoidal residual current device incorporating a time delay. It can be installed upstream from a Type AC RCD to provide selectivity. A time-delayed RCD cannot be used for additional protection because it will not operate within the required time of 40 mS.

Type AC

Type AC RCDs (General Type), which are most commonly installed in dwellings, are designed to be used for alternating sinusoidal residual current to protect equipment which is resistive, capacitive or inductive and without any electronic components.

General Type RCDs do not have a time delay and operate instantaneously on detection of imbalance.

Examples of suitable circuits:

- electric showers

- oven

- hob

- immersion heater, and

- tungsten lighting.

Type AC devices can detect and respond to AC sinusoidal wave current only.

Type A

Type A RCDs are used for alternating sinusoidal residual current and for residual pulsating direct current up to 6 mA.

These are installed to protect circuits where equipment with electronic components are installed such as

- inverters

- Class 1 IT equipment

- power supplies for Class II equipment

- lighting equipment including dimmers and LED drivers,

- induction hobs, and

- electric vehicle charging equipment with smooth residual DC current less than 6 mA.

Type A devices are also suitable for Type AC applications.

Type F

Type F RCDs are used for frequency controlled appliances and equipment.

Examples of equipment include:

- air conditioning controllers with variable speed drives

- some Class I power tools

- washing machines

- dishwashers, and

- tumble driers which contain synchronous motors.

Type F devices are also suitable for Type AC and Type A applications.

Type B

Type B RCDs are used for single and three-phase equipment.

Examples of equipment include:

- inverters

- uninterruptible power supplies (UPS)

- photovoltaic systems

- lifts

- escalators

- welding equipment

- industrial machines, and

- electric vehicle charging equipment with smooth residual DC current which is greater than 6 mA.

Type B devices are also suitable for Type AC, Type A and Type F applications.

How do I test the different Types of RCD?

There are no additional requirements for the installer to check for correct operation whilst subjected to DC residual current. This testing is carried out during the manufacturing process and is called type testing, which is no different from the way we currently rely on circuit-breakers under fault conditions. Type A, B and F RCDs are tested in the same way as an AC RCD. Details of the test procedure and maximum disconnection times can be found in IET Guidance Note 3.

What if I discover a Type AC RCD whilst carrying out an electrical inspection during an electrical installation condition report?

If the inspector is concerned that residual DC current may affect the operation of Type AC RCDs, the client must be informed. The client should be informed of the potential dangers which may arise and an assessment of the amount of residual DC fault current should be made to determine if the RCD is suitable for continued use. Depending on the amount of residual DC fault current, an RCD which is blinded by residual DC fault current is likely not to operate which could be as dangerous as not having an RCD installed in the first place.

In-service reliability of RCDs

Many studies on the in-service reliability have been carried out on RCDs installed in a wide range of installations providing an insight into the effects that environmental conditions and external factors can have on the operation of an RCD.

Key information:

- Devices deemed to be “faulty” when tested on site were removed and tested under laboratory conditions were found to be functional. This was put down to installation conditions or incorrect installation. (Possibly subjected to residual DC fault currents within the installation)

- Many RCDs had been installed in locations which were unsuitable due to environmental conditions.

The key information demonstrates that not only is it important to select the correct type of RCD, also the enclosure for the intended application to protect the RCD from the environmental conditions, to which it will be subjected, is equally as important.

Summary

Assuming an AC Type RCD will suit every installation is incorrect and RCDs shall be selected according to the equipment which is likely to be used within the installation. Type AC RCDs shall only be selected where it can be assured that there is not and will not be any residual DC fault current on the circuit.

Each installation or item of equipment should be assessed for the potential of residual DC fault current and the correct type of RCD shall be selected in accordance with BS 7671:2018 and manufacturer’s instructions.