Evaluation and metrics

All of this is designed to minimise energy loss in the distribution of electricity and reduce energy consumption at the point of use in the electrical installation, whilst still maintaining a suitable and comfortable environment for the end-users.

It should be noted that this is not just about embedding energy efficiency into the design phase though. An electrical installation needs to be fit for purpose throughout its lifespan.

We are all familiar with the requirement of BS 7671 to carry out regular inspections and testing to certify continual electrical safety. The IEC standard suggests an updated energy efficiency assessment at intervals not exceeding three years for industrial and infrastructure installations and five years for commercial installations. Realistically a fresh assessment is advisable when any installation undergoes a significant change in use or load addition.

The introduction to IEC 60634-8-1 states that “this document is intended to provide requirements and recommendations for the electrical part of the energy management system addressed by ISO 50001.” Energy management is the focus of ISO 50001 and it describes a process of regular checks, identifying improvements, remedial works, and further reassessments to ensure that energy management measures remain on track.

Section 4.2 of IEC 60634-8-1 discusses the regular assessment of energy efficiency and states particular periods for commercial and industrial installations when reassessments should take place.

Annex B provides scoring matrices and overall energy efficiency evaluation methods to demonstrate just how efficient the electrical installation is. These are used during the design, installation, and commissioning phases of a project and to provide a benchmark for future improvements. It is worth noting that Annex B is published as “Normative”, so required activity, except in Austria and the UK where it is deemed as “Informative” (refer to Annex C for country-specific information).

The design team should determine the level of energy efficiency measures required. The implementation of these measures should then be monitored through the installation and commissioning stages. The operational team subsequently provide continual assessment and monitoring until the installation is subsequently decommissioned.

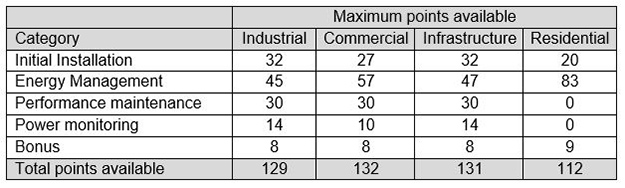

Annex B of IEC 60634-8-1 highlights four principal energy efficiency themes that apply to electrical installations and should be assessed including:

- initial installation

- energy management

- performance maintenance

- power monitoring.

There is also a bonus theme for the inclusion of low carbon technologies.

There are four sectors considered with each of these themes: industrial, commercial, infrastructure and residential. All aspects should be considered for the first three.

An abridged version should be used for the residential and only highlighted energy efficiency measures are applicable. The points allocation is also different for residential installations. For each of the categories there is a short assessment process, sometimes with a calculation where the output is a percentage whilst others are straight yes/no assessment.

If a particular measure is not directly applicable to an installation, it is typically given a score of 0. Where the installation has an LV supply and does not involve a transformer (II04 and MA04 refer) then maximum points are given as it is assumed that the supply authority have already dealt with transformer efficiencies.

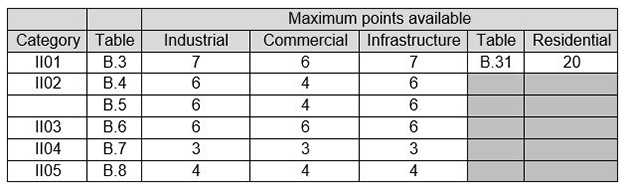

Initial Installation (II) has five categories (II01 to II05) that evaluate the efficiencies within the fixed wiring electrical infrastructure.

I01 assesses, as a percentage, the coverage of energy consumption sub meters so that downstream energy use can monitored. Comprehensive sub-metering is also a factor in Part L of the UK Building Regulations.

II02 looks at the efficiency of the location of the substation and compares distances from the point of supply to the principal switchgear and also to the furthest load using the barycentre calculation method.

II03 looks at voltage drop and is a natural extension of BS 7671 design activities. Circuits which carry 80 % or more of the total energy consumption should be assessed collectively and installations with overall low volt drops score higher points.

II04 is for installations with their own transformer and examines manufacturers data. Higher declared efficiencies will gain higher scores.

II05 assesses the efficiency of the fixed electrical installation and equipment at the point of use. The example in the tables is lighting and ensuring that the same lighting performance is achieved when the energy consumption is minimised. This is also a requirement of Part L of the UK Building Regulations.

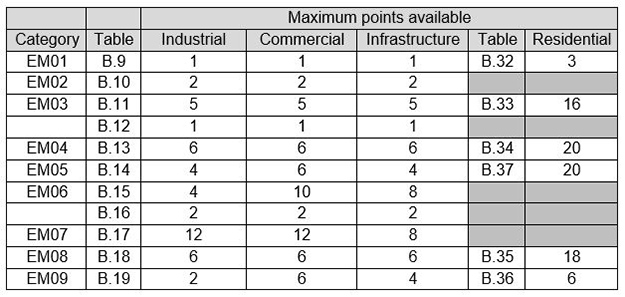

Energy Management (EM) has nine categories and evaluates the deployment and operation of efficient controls at the time of use.

EM01 assesses zones of control and compares the zoned areas (in m2) to the total installation. The requirement is that the installation should ideally have more than 80 % of the electrical installation within control zones.

EM02 assesses usage. Points are awarded where there is comprehensive use of energy meters for a number of usages across the installation and within zones.

EM03 looks at demand response and load shedding controls. There are two aspects covered, the amount of load and the duration. Greater numbers of points are awarded when larger percentage loads are disconnected from the mains grid supply. Similarly, a load that is shed for more than 10 minutes is rewarded under the points system.

EM04 focuses on meshes and refers back to the criteria discussed earlier in IEC 60634-8-1. Where evidence exists of control criteria being considered to determine the meshes, more points can be awarded.

EM05 also assess usages and examines, as a percentage, how comprehensive sub-metering is across the installation for different usages compared to the energy consumption of the whole installation.

EM06 has a couple of tables to check and focuses on the deployment of automatic occupancy controls to reduce operation of the fixed installation when the areas are empty. There are tables for the total area of coverage and for level of occupancy.

EM07 is concerned with the Electrical Energy Management System (EEMS) and assesses how much energy is monitored by the EEMS compared to the overall electrical energy consumption. Bear in mind that an EEMS may form part of a wider energy management system if there are other energy sources.

EM08 assesses controls for heating, ventilation and air conditioning across the installation and points are awarded for general temperature control or room level temperature control or room level time and temperature control.

EM09 focuses attention on lighting controls and compares the amount of automatic lighting controls to the total energy consumption of the lighting across the whole installation.

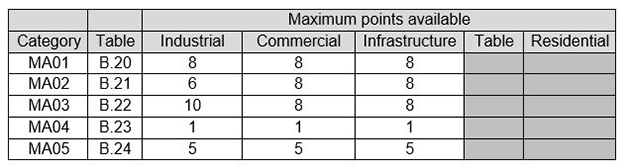

Performance maintenance (MA) has five categories and looks at the processes and procedures to ensure continuous monitoring of energy consumption. Electrical installations will only remain energy efficient if they are maintained regularly and correctly. This is an important aspect of ISO 50001 as well.

MA01 is a “yes or no” assessment and only awards points if there is proof of a satisfactory and auditable maintenance regime in place

MA02 checks the frequency of the checks made on energy performance. Manual checks can be tie consuming, so it is possible that these checks could be automatic and driven by a network of meters connected to a central computer system.

MA03 is about data management and retention of historical data. This is important to track energy consumption trends and could highlight potential issues relatively early. A track record of energy consumption over several years can be an important comparative tool.

MA04 is for installations that have their own transformers and assesses the performance of the transformers. It does this by comparing the actual power used to the optimum working point declared in the manufacturers data sheets. An underutilised transformer will not work quite as efficiently.

MA05 looks at continuous monitoring of large loads (typically more than 10% of the installation’s total energy requirement) coupled with automatic warnings of any variance so that anomalies can be addressed at the earliest opportunity. Large loads could include heating or cooling systems.

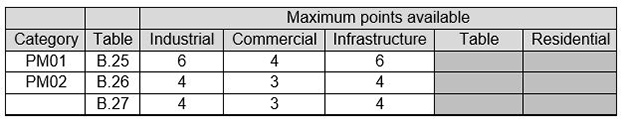

Power monitoring (PM) has two categories that look at how real time power quality analysis is conducted, using appropriate devices, to check power factors and harmonics.

PM01 focuses on power factor correction. It does not specify whether power factor correction should be deployed centrally or at the point of use. The main stipulation is that it is measured at the origin of the installation and maximum points are awarded for a power factor of over 0.95.

PM02 assess total harmonic distortion (THD), again at the origin of the installation. There are tables for THDu (voltage) or THDi (current) and points are awarded depending on the outcome from either table but not both.

It is worth bearing in mind that electricity supply companies typically state the maximum impact they will allow from installations with poor power factors or harmonic distortion.

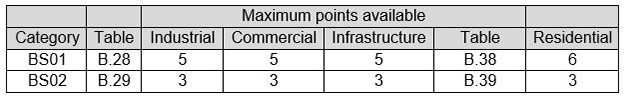

Bonus (BS) provides two further categories to demonstrate deployment of low carbon technologies. These can improve energy efficiency but not all installations will be in a position to use them.

BS01 discusses the deployment of on-site electricity generation through renewable energy sources and compares the output of the renewable source to the total energy consumption of the installation. Renewable sources mentioned include photovoltaic panels and wind turbines. It also includes hydro power, geothermal and biomass.

BS02 looks at electrical energy storage provided it is associated directly with a renewable electrical energy source as described in BS01.

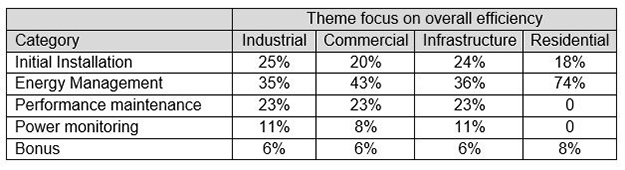

Once each of the categories are assessed all of the points awarded can be added together to provide an overall assessment. It is worth noting where the emphasis on the five themes is for energy efficiency in electrical installations

There is a strong emphasis on the initial installation design and on robust energy management including controls at the point of use. The numbers also stress the importance of a satisfactory maintenance regime.

It is interesting to note that on-site renewable energy supplies and energy storage do not attract high scores. The main focus is on getting the energy efficiency of the electrical installation set up correctly in the first place, monitoring its performance regularly and maintaining that performance.

Renewable energy supplies and energy storage act as an added bonus to installations that are already energy efficient. They should not be seen as a carbon offset for poorly performing installations.

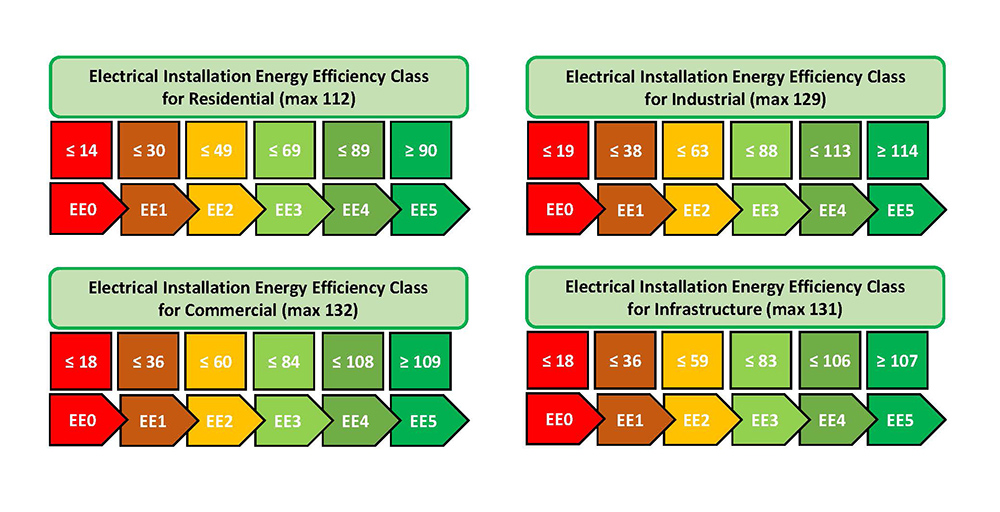

The cumulative score provides the overall electrical installation efficiency classes (EE). The electrical installation efficiency classes are rated from EE0 (low efficiency) to EE5 (high efficiency).

It is important to remember that when a building is occupied and working the EE rating should be regularly monitored and checked. Iterative changes to control settings, maintenance upgrades and improvement projects can always help to set new targets and improve ratings.

Examples of these can include:

- additional metering and sub-metering

- more efficient equipment (e.g. high-efficiency motor specifications, LED lighting)

- controls (e.g. better motor controls and automatic lighting controls)

- introduction of local renewable generation and energy storage.