The history of cable capacities for conduit and trunking

Which factors affect the size of conduit or trunking required?

Firstly, cable calculations are required to determine the appropriate size of conductors taking into account factors, such as the installation method, design current, grouping factor and number of current-carrying conductors.

Once the cross-sectional area (CSA) has been selected, a calculation can be carried out to determine the size of conduit or trunking required. However, it is important to remember that when determining the capacity of a conduit or trunking installation, it is for “drawing in” purposes only in order to prevent mechanical damage to the cables.

It is also important to consider the capacity of trunking with respect to fire-stopping. Fire-stopping products are manufactured from intumescent materials which are designed to expand in volume and density when exposed to heat. There may be a minimum size trunking required to facilitate this process and manufacturers guidance should be followed for trunking or containment.

Where are cable capacities of conduit and trunking in BS 7671:2018+A1:2020?

Regulation 522.8 of BS 7671:2018+A1:2020 sets out the requirements for other mechanical stresses and provides details for erection of conduit systems. However, specific details of cable capacities for conduit and trunking are not provided. This is now left to guidance documents but this has not always been the case, historically they were included in the IEE Wiring Regulations.

When were cable capacities of conduit included in the IEE Wiring Regulations?

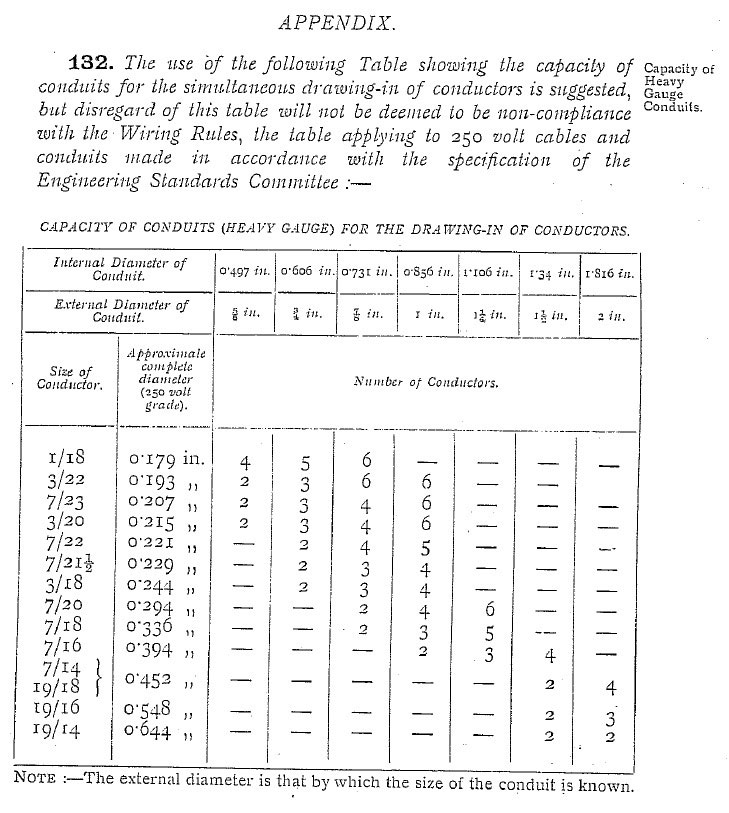

The first table providing cable capacities for conduit was introduced to the Seventh Edition of the IEE Wiring Regulations in 1916 as seen in Figure 1. The table for the drawing in of conductors was included as an Appendix intended for guidance, with the note stating that ‘disregard of this table will not be deemed to be non-compliance'. The table also stated the maximum number of conductors depending on the size of the conduit and conductor. The British Standard Specification for steel conduit and fittings, B.S.S No 31 was first cited in the Eighth Edition of the IEE Wiring Regulations in 1924.

Figure 1: table providing cable capacities for conduit from the Seventh Edition of the IEE Wiring Regulations in 1916

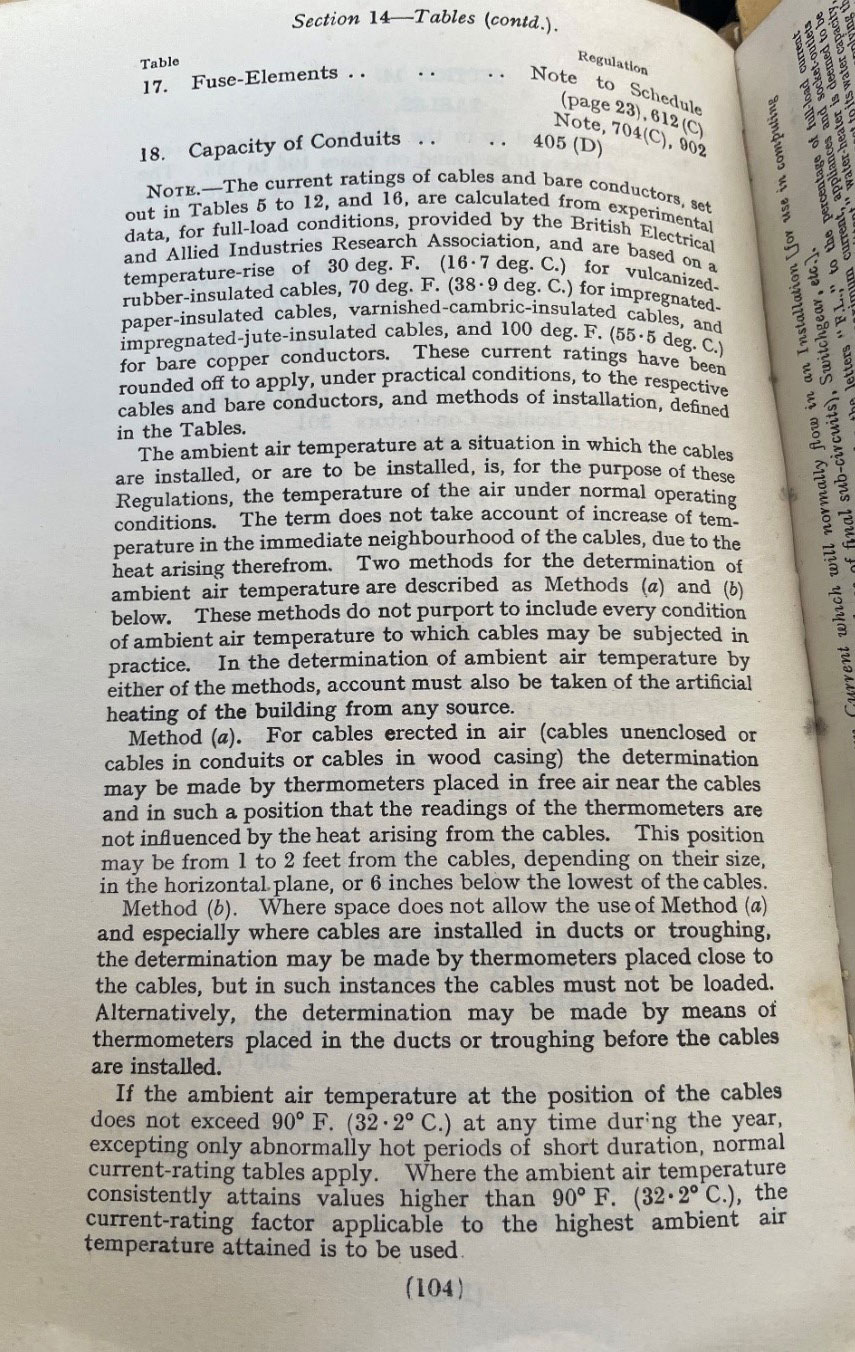

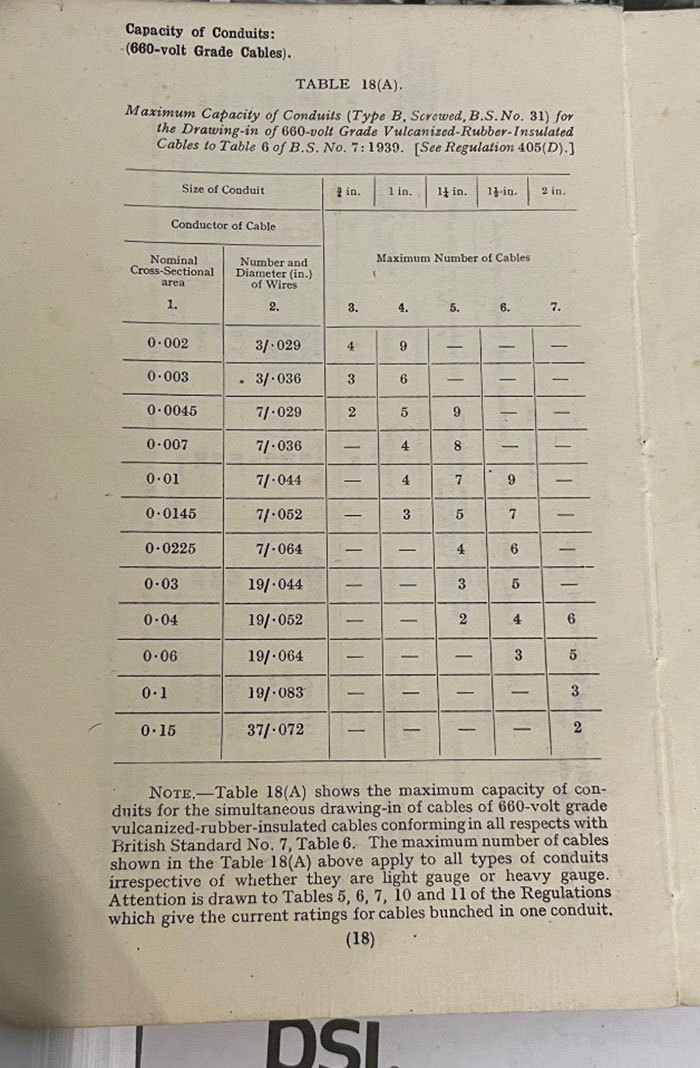

Figure 2 is extracted from the Eleventh Edition of the IEE Wiring Regulations, with the source of the information provided in the tables being experimental work carried out by the British Electrical and Allied Industries Research Association, which later would become ERA technology and now RINA. Table 18(A) was included in the 1946 supplement to the Eleventh Edition of the Wiring Regulations.

Two prescriptive methods for determining ambient air temperature in the ‘immediate neighbourhood of the cables, due to the heat arising therefrom’ were provided using strategically placed thermometers.

Note the reference to using wood casing as containment which came from a recommendation during work to look at measures of reducing materials used in electrical installations. For further information, please see the article on the recommended war emergency relaxations of the IEE Wiring Regulations 1942.

Figure 2: from the Eleventh Edition of the IEE Wiring Regulations

Figure 3: Table 18(A) Eleventh Edition IEE Wiring Regulations

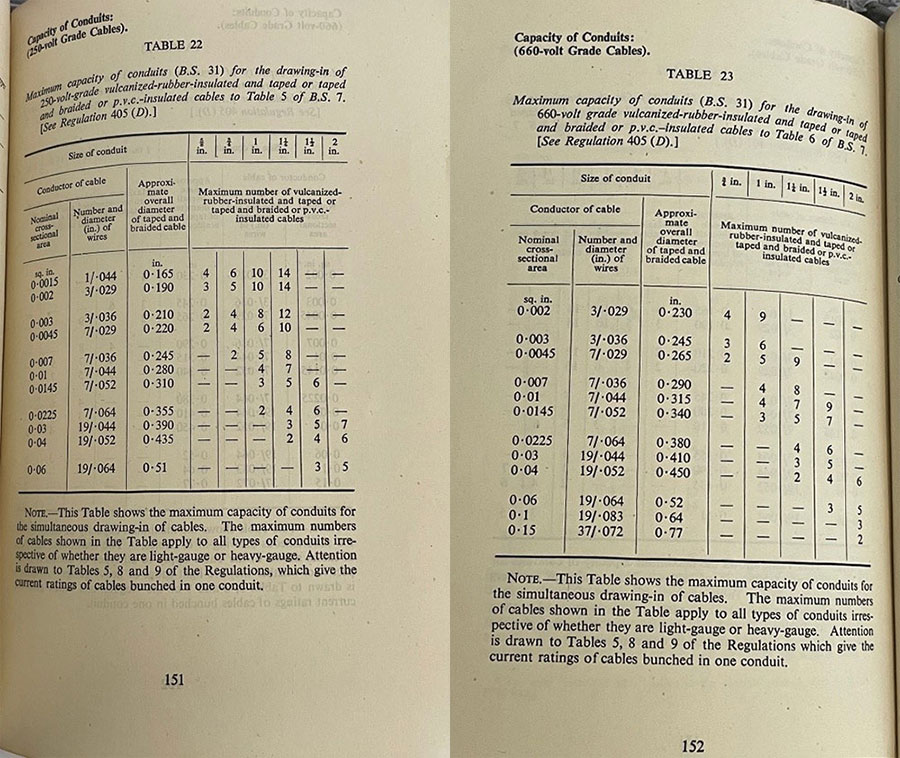

The Twelfth Edition of the IEE Wiring Regulations in 1950 saw the introduction of Table 23 for 660-volt grade vulcanized-rubber-insulated and taped or taped and braided or p.v.c.-insulated cables to Table 6 of B.S. 7, in addition to Table 22 for 250-volt grade cables as seen in Figure 4, this would have been to accommodate the thickness of the additional insulation.

Figure 4: Table 22 and Table 23 Twelfth Edition IEE Wiring Regulations 1950

Is the capacity of a PVC conduit the same as a metal conduit?

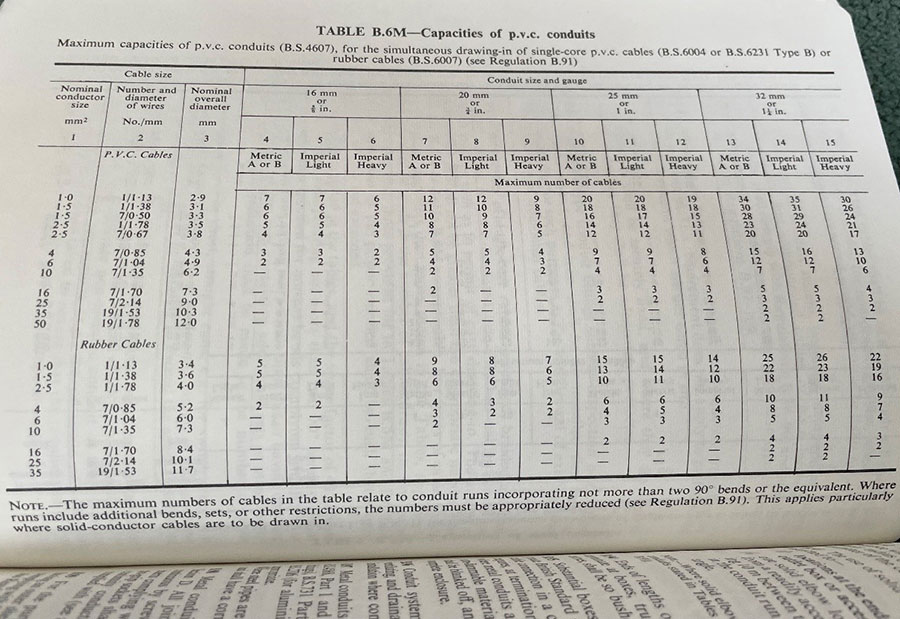

The size of the conduit is referred to in terms of its overall diameter; PVC conduit needs to be thicker than metal to achieve similar mechanical strength, therefore the internal diameter is smaller. An additional table, B.6M for PVC conduit, was included in the Fourteenth Edition of the IEE Wiring Regulations in 1966, which included values for different gauge conduit, it was reprinted to include metric units in 1976 as seen in Figure 5.

Figure 5: Table B.6M Fourteenth Edition IEE Wiring Regulations 1976

When were cable capacities of trunking included in the IEE Wiring Regulations?

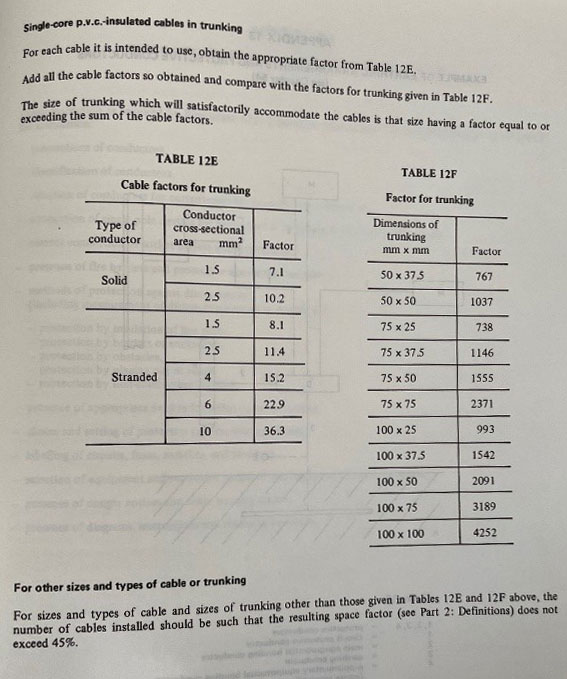

The Fifteenth Edition of the IEE Wiring Regulations was published in 1981 and introduced a new concept for calculating capacities of conduit and trunking, which came from a piece of work carried out by the ERA in association with cable manufacturers. Rather than stating the maximum number and size of conductors for a particular size of conduit, Table 12E and Table 12F of Appendix 12 provided factors for cables and trunking to allow a calculation to be completed to determine a suitable size to accommodate the cables, as seen in Figure 3.

In 1996, IEE Guidance Note 1 provided further background to the tables issued in the Fourteenth Edition of the IEE Wiring Regulations and acknowledged that the previous space factor of 40% for conduit and 45% for trunking was an arbitrary value, later was shown to be inappropriate.

Empirical relationships were deduced through physical testing of drawing in cables and the forces required and whilst there was variation between different manufacturers products, design median values were able to be determined using a unit system.

What are conduit and trunking factors?

Cable, conduit and trunking factors are numerical values associated with physical space. Factors are provided for different types and size conductors as seen in Figure 6, the relevant cable factor is selected and multiplied by the number of conductors to determine the total cable factor which must be less than the relevant conduit or trunking factor.

Figure 6: Factors for different types and size conductors

When were cable capacities of conduit and trunking removed from the IEE Wiring Regulations?

The Sixteenth Edition of the IEE Wiring Regulations was published in 1991 and the tables for capacities of conduits and trunking were not included. Instead, when searching the index for cable capacities of conduit or trunking systems, the requirements for mechanical stresses are referred to in Regulation 522-08, as it is today.

A decision was made by the committee in 1990 to remove notes from the IEE Wiring Regulations, at the time this information was considered to be guidance and not requirements. However, as time moved on notes started to creep back into the Seventeenth Edition of the IET Wiring Regulations and you may be surprised if you search for the number of notes in BS 7671 today. I think most people would agree that in the main, the notes can be useful when trying to interpret the requirements or where further information can be found.

The information contained within the notes was used to form the basis of the IEE Guidance Notes which were first published in 1992. The information relating to capacities of conduit and trunking was also considered to be guidance and is the reason it is no longer included in the Regulations.

Where do I find the cable capacities for conduit and trunking?

Since the information for capacities of conduit and trunking is no longer included in BS 7671:2018+A1:2020, we must rely on guidance material or manufacturers’ information. Further information can be found in IET Guidance Note 1 or Appendix E of the IET On-Site Guide, which provides details of cable capacities for conduit and trunking. It is important to remember that where the type and size of the conductor are not identified in Table E5 and Table E6, the space factor should not exceed 35% for conduit and 45% of the internal CSA for trunking. Space factor is the ratio of free space to the number of cables installed.

Summary

Tables providing capacities of conduit were first introduced in the Seventh Edition of the IEE Wiring Regulations in 1916. The purpose of this information was to prevent damage when simultaneously drawing-in cables, further consideration is required with respect to current-carrying capacity.

Capacities of conduit and trunking have not been included in BS 7671 since 1991 as the information was considered by the committee to be guidance. The IET On-Site Guide and IET Guidance Note 1 provides factors for cables, conduit, and trunking to determine the most appropriate size. Manufacturers of conduit and trunking are best placed to provide information on specific products.