Why have energy efficiency in electrical installations?

In summer 2018, BS 7671:2018 (the 18th Edition of the UK’s IET Wiring Regulations) included a new Appendix (17) concerning energy efficiency in electrical installations. The current proposals for Amendment 2 of BS 7671:2018 develop the initial provisions that have been derived from the international standard IEC 60364-8-1 Low Voltage electrical installations – Part 8-1: Energy Efficiency.

The UK building regulations provide a focus on reducing energy consumption. Most national and international legislative initiatives on energy efficiency focus on the design, construction, and commissioning of new buildings. It is now commonplace that the designs of new installations align with various internationally recognized accreditation schemes.

Relying solely on the implementation of new buildings that reduce energy consumption, to achieve national or international targets, is not enough. To really succeed in reaching global energy targets, energy efficiency measures should be applied to both existing buildings and to new building stock.

The replacement of the existing buildings with new stock is relatively low and is estimated to be around 2% to 5% per annum. Applying a new standard retrospectively to an existing building is always difficult and can be controversial, but IEC 60364-8-1 recognizes this and states that it is “… in the refurbishment of existing buildings that significant overall improvements in energy efficiency can be achieved.”

Design hierarchy

Whether it is a new build or a refurbishment project, there is the need to achieve the lowest possible consumption of electrical energy. Appendix 17 of BS 7671 is an informative section so its contents are not mandatory, but there is clearly a moral imperative to ensure electrical installations do not waste energy. How does this affect the traditional role of the Wiring Regulations?

Within the built environment, the requirements for designing and maintaining safety in electrical installations are governed by national and international standards. International standards may be adopted as they are or might be adapted for local needs by national organizations.

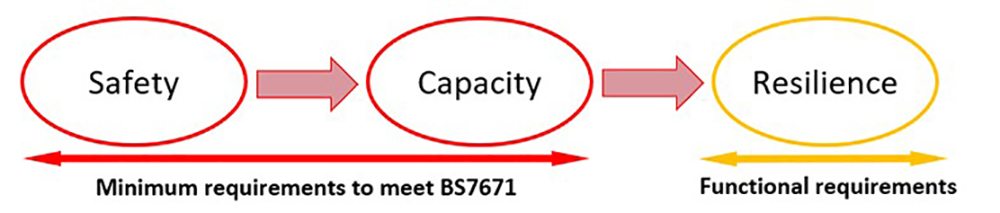

Historically the main two principles of BS 7671 Requirements for Electrical Installations (IET Wiring Regulations) have been safety and capacity. This ensures that an installation should:

- be safe enough to keep operators and users safe from the dangers of electric shock and allow satisfactory maintenance operations; and

- have sufficient design capacity for the existing needs of the installation and to prevent damage to the installation caused by the dangers of heat from overcurrent.

Meeting the requirements of these two basic principles has typically been all that is required for most domestic, commercial, industrial, and infrastructure installations.

Some installations, with safety-critical operations, will also consider resilience as an additional design principle. The requirement might be because of life safety risks, such as acute hospital care, or business continuity in data centres for example. The main purpose is to avoid single points of failure and to provide system continuity.

Embracing safety, capacity, and resilience, the traditional model of an electrical installation design hierarchy has typically been:

As the energy demands of our built environment rise, more burdens are placed on existing electrical distribution infrastructure that could be using quite old equipment and is already overstretched. This will only become more of an issue with the decarbonization of water and the adoption of electric vehicle charge points. This is not just an electrical distribution network issue, this is an issue that needs holistic solutions. We need to reduce energy consumption at the point of use, reduce losses in the distribution network and improve the quality and quantity of supply.

IEC 60364-8-1 considers design and maintenance from the context of reducing inefficiency in electrical installations, whilst still adhering to the original concepts of safety and operational control. Originally published in 2014, it was republished in 2019 and the draft Appendix 17 in the proposed Amendment 2 of BS 7671 addresses this document update.

The inclusion of energy efficiency will require a rethink on the hierarchy of design, but it is important to note that the priorities of safety and capacity will not alter.

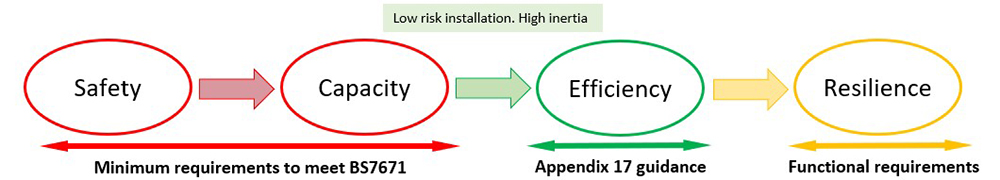

A risk assessment approach is required and will vary from a low-risk installation to a high-risk installation. For installations with low operational risk, the need for energy efficiency may be considered more important when compared to the requirements of infrastructure resilience.

In low-risk installations, any critical loads may be small and supported by localized uninterruptible power supplies (UPS) facilities for specific equipment in a specific area.

Other low-risk loads might not be badly affected by interruptions in supply, or load shedding activities, and can quickly resume normal service (known in IEC 60364-8-1 as high inertia loads). In this instance the traditional design hierarchy may change to this:

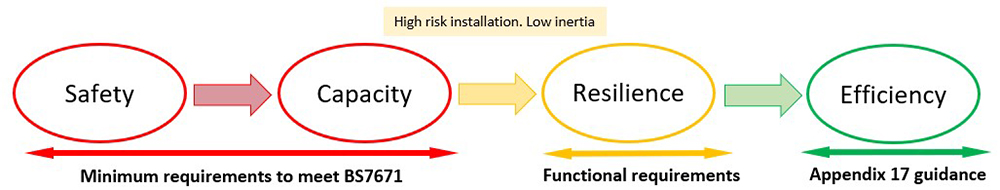

Electrical installations with a high operational risk may have a different approach, for example where there are greater risks to the critical healthcare of patients, or in financial institutions with major business continuity considerations.

In high-risk installations, critical loads will be significant, with large UPS facilities and backup generators to support an array of equipment across a large part of the installation. These types of loads will be badly affected by interruptions in power supplies, or load shedding activities, and cannot quickly recover (known in IEC 60364-8-1 as low inertia loads).

Interruptions in electrical supplies are always inconvenient. However, in high-risk installations, this could also lead to dangerous situations for hospital patients or loss of significant business in an international bank. Here the traditional design hierarchy will probably need to place much more emphasis on the principle of resilience and make energy efficiency a necessary but lower priority.

Whichever approach is ultimately adopted, there should still be a change of emphasis at the design stage to incorporate energy efficiency into electrical installation designs, and by default into operations as a prerequisite, not just as an aspiration. However, with the guidance offered, this does not need to be overly onerous or complicated. Indeed, many of the measures highlighted are common sense to aid efficient operations and others are already considered as part of a safety approach to electrical designs and installation.

The implications of energy efficiency on designs

Energy efficiency has not been addressed in an obvious way within previous editions of BS 7671, including the 2015 amendment of the 17th Edition.

Requirements for reducing volt drops on distribution and -circuit cables are primarily focused on ensuring proper operation of equipment at the point of use. However, having the correct voltage at the point of use can also affect the operational efficiency of some electrical equipment.

Requirements on correct current carrying capacity reduce the risk of undersized cables and subsequent fire risks. However, having the correct sized cables is also a useful tool for addressing inefficiencies caused by harmonics of certain types of electrical equipment.

Within the Wiring Regulations, any discussion on controls and circuit switching has been about safe systems of work and functional operations. However, there has previously been no explicit mention of controls in the context of automatically reducing energy consumption. Sensors to control lighting have been become commonplace in recent years and used in conjunction with functional switching. It is these automatic switching and controls that are highlighted with the electrical energy efficiency standard.

Designing for power factor correction (PFC) has been considered previously, but usually just at the intake switchboard to improve load characteristics at the point of supply. The premise of energy efficiency is to reduce throughout the electrical distribution infrastructure, from the point of use to the point of supply. The designer should think about energy efficiency in a holistic way, throughout the whole installation. For instance, just focusing on power factor correction at the main switchboard may no longer be sufficient. Now, other methods of power factor correction should be considered, including:

- small PFC units connected directly to large plant such as chillers

- use of more efficient equipment meaning less PFC is actually required, or

- small PFC directly connected to local switchboards.

Although not addressing energy efficiency, surge protection devices follow a similar integrated model and are increasingly being used throughout electrical installations. Using the surge protection model, localized PFC, and harmonic filters should be considered throughout the electrical distribution system to assist with energy efficiency. Such an approach will optimize the whole installation and potentially reduce oversizing cables.

Design factors

IEC 60364-8-1 considers various design and operational factors for energy efficiency in electrical installations. Each of these factors approaches the energy efficiency question from a slightly different perspective to provide a holistic view.

-

Load energy profile (active and reactive energy)

This looks at the type of electrical loads and what measures can be put in place at the point of use to mitigate and reduce energy losses on the electrical distribution caused by equipment connected to it. By monitoring, measuring and analysing energy consumption, patterns of typical use, and misuse can be recognized so that action can be taken

-

Availability of local generation (PV, wind turbine, generator, etc.) and storage

This looks at the availability of on-site generation of electricity to reduce the demand of the installation on the wider grid. It will also include local electrical energy storage. Controls should be considered carefully to make best use of on-site generation or storage, especially at times of peak grid demand and higher prices.

-

Reduction of energy losses in the electrical installation

This looks at active measures such as power factor correction and harmonic filters and also passive measures to ensure cable infrastructure and other components are sized correctly to minimize losses. The proximity of the point of supply to the point of use should also be assessed, using the technique if applicable, to minimize losses on the distribution system by reducing distance between intake and load. The correct selection of energy-efficient electrical appliances that are permanently connected to the installation is also important.

-

The arrangement of the circuits with regard to energy efficiency

This looks at how the circuits are grouped through zones, usages, or meshes. Requirements for zones focus on geography of circuits and loads, while usages deal with particular types of loads that are heavy users of electricity e.g. motors, air conditioning, or lighting. Meshes consider how the zones and usages integrate and how this is all monitored and controlled

-

The customer's power use distribution over time

This assesses which electrical loads are active at what times. Scheduling can be initiated to avoid capacity issues at the electrical intake and to avoid punitive costs for unnecessary energy consumption at peak times. Shifting the energy consumption of some loads to off-peak periods could be rewarded of cheaper tariffs at the time of use using contractual incentives from the electricity supplier. Load shedding may also be considered necessary.

-

The tariff structure offered by the supplier of the electrical energy

The roll-out of smart meters allow for the introduction of dynamic tariffs that vary throughout the day. Traditional tariffs can feel like they are one-size-fits-all and have higher costs. Newer entries to the electricity supply market, like Octopus Agile, offer half-hourly rates to the market allowing customers to plan their consumption through the whole 24-hour period. Loads like electric vehicles and electrified heating can be supported through off-peak hours when tariffs are significantly cheaper.

The case for energy efficiency in all electrical installations

Most legislative initiatives and associated benchmarking schemes on energy efficiency focus their outcomes primarily on new buildings. In order to improve, or promote, their environmental credentials, many newly built installations seek accreditation from international organizations such as BREEAM, LEED or similar benchmarks. These awards are driven during the design stage of new construction projects.

Refurbishment has not always had the attention or emphasis it needs. For refurbishment projects, similar benchmarks have not always been available. Changes in recent years to the UK Building Regulations, including Part L, which focuses on energy consumption, means that if a large enough part of the building is refurbished the other parts of the same refurbished building must also be considered for upgrade too – the idea of beneficial improvements.

Another driver for change in the UK is in the commercial rental sector. This means that commercial buildings must achieve minimum energy efficiency standards before they can be let.

An energy-efficient electrical installation has many potential benefits:

- It generally has less impact on the environment.

- It reduces energy losses overall and hence lowers energy costs.

- It has better controls and uses energy only when it is actually required and potentially at a lower (off-peak) tariff.

- It means less reactive maintenance throughout the electrical infrastructure by reducing the adverse effects of heat loss, and

- It optimizes the electrical system performance throughout its life cycle.

Conclusion

Safety and capacity are still the most important criteria for electrical installations covered by BS 7671. Resilience should always be considered especially on life safety systems.

However, energy efficiency is a necessity and can no longer be ignored as we move to a low-carbon future. The guidance within Appendix 17 and in IEC 60364-8-1 should underpin all electrical installations by design and by operation.

Designers and operators should be aware that there is now a duty of care to make their electrical installations as efficient as possible without reducing safety or compromising the needs of users or activities within the buildings. Design risk assessments of electrical energy consumption are likely to become as important within the built environment as health and safety or reducing single points of failure.