Mythbusters #3 – All electrical appliances in the workplace should be tested annually

As the IET Code of Practice for In-service Inspection and Testing of Electrical Equipment undergoes revision in preparation for a 5th Edition, James Eade delves into the archives to look at the rationale for testing and where such established practice comes from.

History

The introduction of the Electricity at Work Regulations in 1989 reinforced the need to make sure that electrical equipment in the workplace was kept safe and unlikely to cause injury or damage, such as by causing a fire. In the early nineties, the (then) IEE was asked to write guidance to help those dutyholders responsible for electrical equipment to manage it effectively. A committee of interested parties was formed and guidance duly published in 1994, with successive updates in 2001, 2007 and the current 4th Edition published in 2012.

The approach to testing

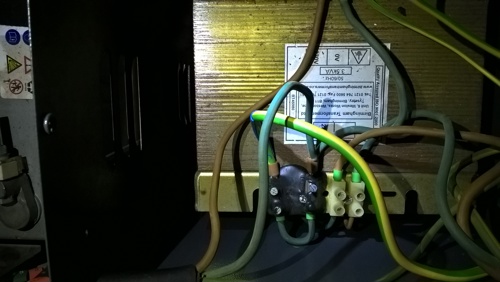

Many of the tests and associated results in the earlier editions of the Code were inspired by the manufacturers' ‘type testing’ on products, carried out in the final stages of manufacturing. These comprise a range of stringent electrical tests aimed at ensuring protection (such as insulation or electrical separation) is unlikely to breakdown in the variety of conditions that the equipment will typically be exposed to in use.

These tests are broadly the same today. One that some readers may be familiar with is a high-potential (i.e. high voltage) test in the order of 1000 V or more to check insulation. Many readers might remember that early appliance test instruments used to have a high voltage probe to allow users to conduct the ‘flash-test’ for that reason.

It’s accepted that exposing equipment to such stringent manufacturing tests repeatedly risks damaging it in the long term, rather than proving safety to a point beyond what can be achieved with basic checks. Over time the focus has been more on ensuring that the safety measures such as insulation or earthed exposed metalwork is in good order; this has led to some of the tests disappearing over time.

The earlier editions also included the range of manufacturers’ tests as Appendices. However, the approach to testing changed as noted in the preface to the third Edition, which stated that “Production testing, previously included in this Code of Practice, has been removed as it is not relevant to in-service inspection and testing.”

The need for maintenance

One of the key requirements of the law is that electrical equipment does not give rise to the risk of injury or damage. The Electricity at Work Regulations requires in Regulation 4 (2) that, “As may be necessary to prevent danger, all systems shall be maintained to prevent, so far as is reasonably practicable, such danger.”

The HSE’s publication HSR25 The Electricity at Work Regulations, 1989. Guidance on Regulations (free to download from www.hse.gov.uk) states that, “The obligation to maintain arises only if danger would otherwise result. The maintenance should be sufficient to prevent danger so far as is reasonably practicable.”

It goes on to note that the “regular inspection of equipment is an essential part of any preventive maintenance programme”, which is in many respects an obvious statement. If equipment is broken, it’s not fulfilling a business need so productivity is likely to suffer accordingly.

‘Regular’ maintenance

That all sounds perfectly reasonable, but if you are the dutyholder trying to plan such maintenance, you stumble over the ‘regular maintenance’ statement. What exactly is ‘regular’? Every day? Week? Year? For those trying to populate a maintenance plan in a spreadsheet, such grey statements are not helpful.

In order to help address that, the Code has carried initial inspection and testing intervals in Table 7.1 for some time, to try and help dutyholders by giving them an indication of what might be considered a reasonable period. However, these intervals have always been guideline initial intervals; i.e. a period which could be considered reasonable for the first maintenance activity to be carried out, from whence it can made more or less frequent.

In the third Edition, the Code reinforced this position by stating that “No rigid guidelines can be laid down”. The fourth Edition went further by saying, “Table 7.1 provides only some guidance on the initial frequencies of inspection and testing. It is not an absolute legal requirement and should not be considered as such.” Despite these statements, the intervals have found themselves being used as ‘prescribed’ intervals and a ‘requirement of the Code of Practice’, which of course they are anything but.

To help address this, the fourth Edition encouraged the reader to consider the risk. In particular, readers were encouraged to think of seven areas ranging from the environment equipment is used in, the skill of the user, the equipment and construction (Class I, II etc.), frequency of use and so on.

In essence, there is no right or wrong answer as to the frequency of maintenance; it’s either suitable or it isn’t. Looking at it another way, if a company suffers with regular equipment downtime or, worse still, people get injured by faulty equipment, then maintenance is not sufficient. Alternatively, it may be that the type of equipment is incorrect for the environment or the application, or the user hasn’t been sufficiently trained. The correct equipment for the job, operated by skilled users and maintained effectively should give largely trouble-free service. If there are no issues then maintenance is either just right, or is possibly being overdone.

Conclusion

The key message, reinforced in the HSE’s own equipment testing guidance, is that annual testing may well not be the right answer. There is an absolute legal duty of employers to ensure maintenance is carried out and is effective, but dutyholders must decide for themselves what is reasonable and proportional.

Perhaps the final word should go to the HSE’s guidance in HSR25 again: “Practical experience of use may indicate an adjustment to the frequency at which preventive maintenance needs to be carried out. This is a matter for the judgement of the dutyholder who should seek all the information he needs to make this judgement including reference to the equipment manufacturer’s guidance.”

The fifth Edition of the IET Code (due out early 2020) is likely to reinforce the risk assessment requirement. It’ll be a significant revision with a more streamlined approach, greater clarity on what equipment is (and isn’t) in scope and clearer guidance to enable dutyholders to assess the risk and develop a maintenance program. Following the changes, it is also likely that industry training courses will need to be updated, so new or update courses might become available to help practitioners demonstrate competence with the changes introduced in the new Code. As is the case now, these courses won’t be a requirement at all, but a means of demonstrating that candidates have the underpinning knowledge to help them conduct in-service inspection and testing.

There is the usual caveat though: The Code of Practice is work in progress so things may change, so watch this space. For more information on managing electrical risks in the workplace, the IET has two other publications on the subject – the Code of Practice for Electrical Safety Management and the Guide to Electrical Maintenance.