Electrical maintenance: a framework for good practice

The background

The first edition of the IET Guide to Electrical Maintenance was published in 2015. It built on the legacy of previous IEE publications that had focused on specific aspects of electrical installation maintenance. About eighteen months ago the editorial committee was reconvened with new members and set to work to evaluate the format and content of the first edition. A partial rewrite and insertion of additional material followed. The revised and updated second edition received close scrutiny and valuable contributions from the editorial committee and from several others who became involved at the DPC stage. It is now ready for publication and relaunch.

The first edition noted that good maintenance regimes do not happen by accident: they need careful planning, proactive management, and comprehensive reporting. The tone for successful maintenance outcomes and processes should be established beforehand by considerate design, intelligent construction, and satisfactory commissioning. Industry initiatives and programmes such a Soft Landings draw a definitive link between good design, robust construction and successful maintenance across all installations, not just electrical installation. A good design should always consider the installation from various perspectives such as ease of installation, facilitating commissioning and maintenance including decommissioning and replacement.

The maintenance team must be seen as a key stakeholder in consultations during the design and the construction phase of a project. Proper assessment of the connections to the existing infrastructure should be thought through to ensure that the infrastructure can support the new build and can also deal with seasonal demands. Any residual design risks going forward should be noted to allow for future growth and any planning that needs to be assessed. That information will help inform the next project designers.

Robust maintenance regimes do not just start with a project handover. They should start far earlier. Project handover, with a comprehensive and site-specific Operation and Maintenance (O&M) Manual, should indicate that correctly managed and documented maintenance practices have already commenced. The only maintenance management process left to start should be regular auditing and any consequent replacement of expired equipment.

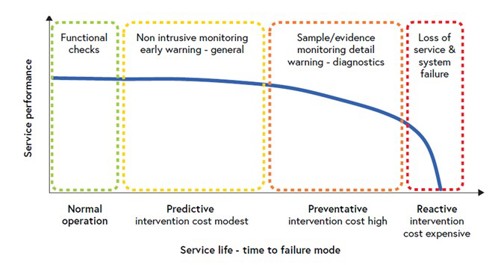

Understanding the strategies for maintenance and knowing when to use them is a responsibility for maintenance managers and technicians alike. Different responses will be required for preventative, reactive or predictive maintenance. Relative costs will also influence the required maintenance strategy. Electrical equipment has become increasingly more efficient and better controlled, but it all has a limited lifespan. Maintenance is a necessity, not an inconvenient overhead and the associated costs can be influenced by good design and by maintenance strategy management.

Figure 1 The relative cost of maintenance intervention

It has to be recognised that robust electrical maintenance regimes have a significant role in a more sustainable world where electrified heat, low carbon technologies and on-site electrical generation are now mainstream installations. Modern electrical installation designs are using technologies that consume less energy during their lifespan, but only if they are looked after properly. Correctly maintained electrical systems will keep operating at optimum energy efficiency for far longer, help reduce energy consumption and minimise carbon emissions.

Energy costs have been trending upwards for many years and has accelerated recently. The financial imperative of a well maintained, low energy electrical installation needs to be correctly appreciated by the business manager – otherwise poor maintenance will undermine the bottom line.

The second edition provides updates to the original text and introduces additional items and areas for consideration as part of a maintenance programme. It also redefines the guide as a reference document for both the management of electrical maintenance and also the practicalities of electrical maintenance activities across a range of activities.

The original management related sections of the 1st edition are now part of a new main Section 1 which focuses on the administration and policy of maintenance with additional content and diagrams.

A refreshed framework

Appendix B of the 1st edition now forms a new Section 2 of this refreshed publication. It provides a greater focus on the practical aspects across a wide range of electrical installations. Additional topics are added such as heat pumps and electric vehicle charge points.

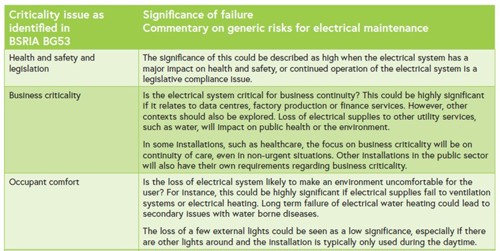

Section 2 looks at specific electrical maintenance tasks in a number of areas from a risk assessment approach that is based around the format suggested in BSRIA BG53 Business-Focused Maintenance.

The BG53 format has been adapted to appraise various electrical systems and inform on the urgency of some maintenance tasks over others to make it a more practical tool for technicians and supervisors alike. By following the process, it can be used as a framework for other site-specific tasks not covered in this edition. It provides a mechanism that supports careful assessment of engineering systems to ensure continued health and safety, business continuity and comfort of occupants. The premise is that this method can be adapted and further developed by the reader over a number of other electrical systems specific to their particular electrical installation and not just focus on buildings.

Section 2 focuses on four key areas of electrical maintenance: Energy input to electrical systems, general applications and circuit protection, life safety systems and also industrial equipment and associated control systems.

The beginning of each key area provides a table that examines critical issues such as health and safety, business criticality and occupant comfort. The significance of failure is examined and sets the context for maintenance of these electrical systems. Further issues such as client image and status, asset life and environment and sustainability can also be assessed in the same critical issues analysis.

Figure 2 Generic critical issues examples

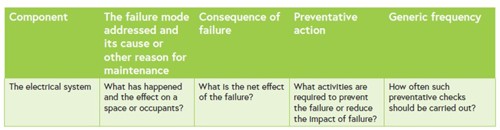

Detailed focus on a number of topics looks at task specific risks and their mitigating actions. The tables look at specific maintenance risks on different parts of the electrical installation and evaluates failure modes, consequence of failure, preventative action and advises on frequency of activity. A total of 31 electrical maintenance topics are covered in Section 2 based around the four key areas outlined above. The layout and format of these tables allows the reader to add further site-specific topics and evaluate the related tasks in easy steps.

Figure 3 Task specific risks and mitigating actions

Electrical maintenance places specific legislative and regulatory responsibilities on the occupier of a building and associated premises as duty-holders to ensure the continued safety of electrical installations. The new Building Safety Act 2022 could add to these duties. There are already statutory obligations to ensure the successful operation of life safety systems, such as emergency lighting and fire detection and alarm systems, when they are actually needed. The maintenance of such systems and the associated audit trail in high-risk buildings, for instance, will become more important.

Transportation systems such as lifts, escalators and moving walkways also need periodic assessment. Insurance policies may be an additional driver of this – if periodic certification cannot be produced then insurance policies may not be honoured if the need arises.

BS 7671 (the IET Wiring Regulations) and the accompanying Guidance Notes discuss the periodic testing and inspection that should be at the heart of any maintenance regime for the premises’ electrical installation.

Maintenance activity, especially on life safety systems, needs to be recorded and signed off. To demonstrate compliance of fire alarms, emergency lighting and similar systems with statutory requirements a logbook recording periodic tests should be used. This, in turn, must be left available for auditing purposes. Dates of test, anomalies, and remedial actions should all be noted.

Exit strategy

We should all be considering our impact on the planet. Within the electrical industry many of the materials we use should be assessed for reuse or safe disposal. The final obligation of the maintainer is to ensure that all time-expired equipment is disposed of correctly at the end of its lifecycle. Regulations need to be considered here too as most electrical and electronic equipment at the end of their useful life will be covered by the Waste Electrical and Electronic Equipment Directive.

Summary

There is a lot more to electrical maintenance than just turning up with a toolbox and pack of lamps or a replacement faceplate. You should not run your car without an annual MOT and regular servicing of the vehicle is advisable. Do not neglect your electrical installation either.

Make sure you understand how to maintain under a safe system of work and how to reinstate carefully. Evaluate the maintenance risks to the maintainer and the end user of the installations. Monitor costs, evaluate maintenance strategy and make informed decisions on when to intervene and ensure continuity of service.

Guide to Electrical Maintenance, 2nd Edition

https://shop.theiet.org/electricalmaintenance

ISBN-13: 978-1-83953-492-8