Socket-outlet protectors

The safe system that is BS 1363

Accessories to BS 1363 are designed and made to exacting requirements so that the plug perfectly fits the socket-outlet. When the BS 1363 system was defined in the 1940s, designers wanted to make sure that the socket-outlet was very safe. The Standard requires that an interlocking shutter system stops foreign objects from being inserted into the socket contacts and that all socket-outlets are tested to ensure that a pin has to be inserted a distance of 9.6 mm into the socket-outlet aperture before it makes contact with any internal live parts. The shutter system will operate and open to expose the line and neutral contacts only when the plug is inserted. This can be achieved by:

- the earth pin of the plug, or

- both the line and neutral pins of the plug simultaneously, or

- all three pins: first the earth pin, followed by both the line and neutral pins simultaneously.

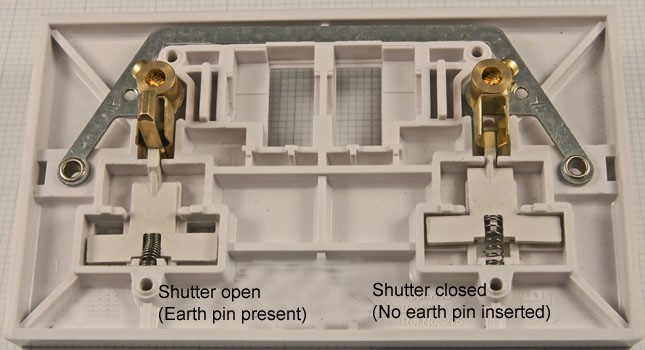

An earth-pin-operated shutter mechanism is shown in Figure 2.

Figure 2: Image courtesy of Fatally Flawed

An earth pin has been inserted into the socket-outlet on the left, and the shutters that normally cover the socket-outlet contacts have opened. There is nothing inserted in the socket-outlet on the right, and hence the shutters are closed.

BS 1363 socket-outlets already incorporate a shutter mechanism that prevents intentional and unintentional direct contact with internal live parts.

Dangers

The intended function of the socket-outlet protector sounds simple – but the reality can be quite the opposite. There is no standard for socket protector design and performance and products available on the market can vary in terms of quality and dimension. The pins of socket-outlet protectors are rarely the same size as a 13A plug; they are usually wider or narrower.

Where the pins are wider than a 13A plug, the socket-outlet protector can widen and deform the spring contact in the socket-outlet, ultimately resulting in permanent damage and poor electrical contact with the socket-outlet. This may lead to potential arcing and overheating in normal use.

In addition, withdrawing an oversized socket-outlet protector is likely to be difficult, as it can become effectively wedged in the socket-outlet. In such cases, forcing the protector out of the socket-outlet with whatever tools are to hand can damage the socket-outlet and lead to more danger. Where the pins of the socket-outlet protector are narrower than a 13A plug, the socket protector can be easily withdrawn from the socket-outlet, thus defeating its purpose.

Further to the physical dimensions of the socket-outlet protector, the next consideration is the material from which it is made. If the material is too brittle, the socket-outlet protector might snap during its withdrawal operation, leaving a pin in the socket-outlet contact and thus exposing other socket-outlet contacts, as the shutter mechanism has been defeated. Where the material is overly malleable or too soft, socket-outlet protectors can be inserted upside down, which can operate the safety shutter mechanism and expose live parts; see Figures 3 and 4.

Figure 3

(Image courtesy of Fatally Flawed)

Figure 4

(Image courtesy of Fatally Flawed)

“Using a non-standard system to protect a long-established safe system makes no sense.”

What does BS 7671:2018+A1:2020 require?

Regulation 553.1.201 states: “Every socket-outlet for household and similar use shall be of the shuttered type and, for an AC installation, shall preferably be of a type complying with BS 1363.”

Socket-outlets in excess of 13A, such as industrial types to BS EN 60309-2, are available in current ratings of 16, 32, 63 and 125A, but are not intended for household or similar use. Generally, these socket-outlets do not incorporate an integral shutter system.

Where did it all start?

During the Second World War, the government of the day commissioned a number of reports that looked at how the country could rebuild once the war was over. Discussions on the ‘Post-War Building Studies’ were convened by the Institution of Electrical Engineers (the IEE - forerunner of the IET) and the committee was charged with the following:

1. To review existing information and practice concerning installations in buildings for:

a.) the supply of electricity for all purposes from the point of entry of the current at the property boundary to the point of its delivery to an appliance

b.) electrical household appliances serving the single-family dwelling; and

c.)all forms of electrically operated telecommunications.

2. To review proposals for improved electrical appliances for space heating, cooking, refrigeration, hot-water supply, dish washing, and clothes washing.

3. To make recommendations for practice in post-war building (projects).

Post War Building Study No.11 ‘Electrical Installations’ was published in 1944. Section 76 gave birth to the ring-final circuit:

“We recommend that small dwellings of the types considered should be wired with three separate circuits for lighting, cooking, and socket-outlets respectively, each controlled by a separate single-pole fuse. It is proposed that all socket-outlets should be supplied from a ‘ring circuit’ which, starting and ending at the fuse terminal at the consumer’s supply control will pass through each room in turn. In the small dwellings under consideration, it is considered permissible to connect up to 20 of the proposed standard socket-outlets on the ring circuit. At the consumer’s supply control, the ring circuit will be fused for 30 amperes, a current which is unlikely to be exceeded in the conditions of load diversity met within small dwellings. At each outlet position on the ring circuit, it will be necessary to provide a cartridge-type fuse for local protection.

With regard to the socket-outlet circuit, the recommendation to connect a number of standard socket-outlets on a ring circuit represents a departure from existing practice as laid down in the Wiring Regulations (Eleventh Edition).”

With ring circuits rated at 30 A and up to twenty socket-outlets connected to the circuit, it was necessary to incorporate a fuse on the appliance side of the electrical system. This led to the development of British Standard 1363:1947 Fused Plugs and Shuttered Socket-Outlets, introduced in 1947.

Last word

Socket-outlets to BS 1363 are the safest in the world and have been since they were first designed in the 1940s. Socket-outlet protectors are not regulated for safety: using a non-standard system to protect a long-established safe system is not sensible and can create potential electric shock and fire hazards.

Thanks

BEAMA: UK trade association for manufacturers and providers of energy infrastructure technologies and systems

Special thanks to David Peacock (Fatally Flawed) who, very sadly, passed away in November 2018.

Further information and reading

BS 1363-2:2016+A1:2018 '13 A plugs, socket-outlets, adaptors and connection units. Specification for 13 A switched and unswitched socket-outlets'

The Plugs and Sockets etc. (Safety) Regulations 1994