Mythbusters #4 Double insulated cables

He noted that technicians often consider that:

- Meter tails are regarded as being double insulated; and

- Steel Wire Armoured (SWA) cables are regarded as having reinforced insulation.

Before looking at these, it is worth revisiting the principle of protective measures against electric shock. Generally, electrical systems in common use comprise a protective measure consisting of basic protection and fault protection. Older readers may be more familiar with the old terms for these, namely direct contact and indirect contact respectively.

There are four common protective measures as given in Regulation 410.3.3 of BS 7671:2018:

1. Automatic disconnection of supply (Section 411)

2. Double or reinforced insulation (Section 412)

3. Electrical separation (Section 413), and

4. Extra-low voltage provided by SELV or PELV (Section 414).

All of the above have a requirement for basic protection, which is the primary line of defence against electric shock and is typically achieved by insulation over the live parts, such as the insulation around a conductor, or a barrier inside an enclosure. The requirements for basic protection are described in Section 416.

Fault protection is the second line of defence, preventing (or limiting the effects of) an electric shock in the event that the basic insulation fails. In the case of automatic disconnection, a fault to the earthed exposed-conductive-parts results in operation of a circuit-breaker, fuse or RCD, thereby disconnecting the circuit and protecting the user and the installation.

Double or reinforced insulation is another method of protection against electric shock, consisting of an extra layer of supplementary insulation over the basic insulation, or a single layer of special reinforced insulation directly over the live parts. The latter provides basic and fault protection in one application and is commonly found in power tools for example. Class II products complying with the requirements for double or reinforced insulation in electrical safety standards will be marked with the double insulated symbol. It is possible to erect an entire electrical installation using only double or reinforced insulation as the protective measure, with all equipment – as well as the installation of wiring and accessories – complying with Section 412. Such an installation must be subject to effective measures (such as supervision) to ensure that no changes could be made that would impair the safety of the installation, as may happen if electrical equipment with exposed-conductive-parts is introduced.

Electrical separation as per Section 413 is commonly achieved by using a source which may be an electronic power supply or an electromagnetic transformer that provides at least simple separation. Fault protection is achieved by separating the secondary side from Earth and other circuits, thereby preventing the user from getting an electric shock to Earth. Finally, the extra-low voltages described in Section 414 again require basic protection between live conductors, but shock protection is achieved by the low voltages in the installation, which should be provided from a source meeting certain safety requirements.

Are meter tails double insulated?

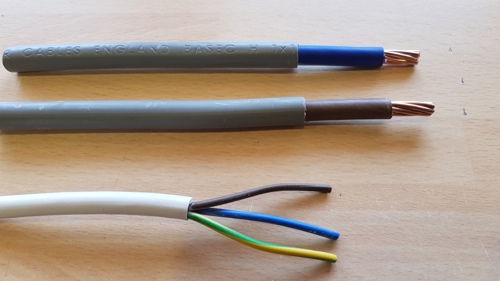

Technically no, because meter tails are not a protective measure in the installation designed to prevent the user from the risk of electric shock, like automatic disconnection, or electrical separation. More correctly such tails should be referred to as ‘insulated and sheathed’ cables, just as flat twin-and-earth or H07-RN-F flexible cables are.

However, it is evident that having two layers of insulation would appear to fulfil the requirements for both basic and fault protection, and this is noted in Regulation 412.2.4:

412.2.4 Wiring systems

412.2.4.1 Wiring systems installed in accordance with Chapter 52 are considered to meet the requirements of Regulation 412.2 if:

i. the rated voltage of the cable(s) is not less than the nominal voltage of the system and at least 300/500 V, and

ii. adequate mechanical protection of the basic insulation is provided by one or more of the following:

a. The non-metallic sheath of the cable

b. Non-metallic trunking or ducting complying with the BS EN 50085 series of standards, or non-metallic conduit complying with the BS EN 61386 series of standards.

So, for meter tails or other insulated and sheathed cables, the basic insulation over the conductor and the non-metallic sheath are deemed to comply with the requirements for both basic and fault protection in Regulation 412.2 and hence don’t need to be installed in containment (unless required for mechanical protection). What this also means is that removal of the outer sheath to enable the colour of the core to be identified outside of a wiring accessory (e.g. a meter or service block) should not be done, as the cable will have been reduced to having basic insulation only. The IET On-Site Guide has more information on meter tails in Section 2.2.3.

By the same rationale, an SWA cable does not have reinforced insulation. The wire armour is there for mechanical protection of the cable. Reinforced insulation is defined as:

“Single insulation applied to live parts, which provides a degree of protection against electric shock equivalent to double insulation under the conditions specified in the relevant standard. The term ‘single insulation’ does not imply that the insulation must be one homogeneous piece. It may comprise two or more layers which cannot be tested singly as supplementary or basic insulation.”

So, just because the cables meet the requirements for double insulation as a protective measure, it doesn’t mean that cables are double insulated products.

Insulated and sheathed cables such as these are not double insulated products