Safe isolation: stories that could save lives - are you sure you are safe?

This is the first article in a series of safe isolation stories.

For thousands of years, humans have used stories as a method of warning each other of dangers and for sharing experiences.

As pressure increases on the electrical industry to train thousands of additional apprentices annually, due to net zero targets, it is important to recognize that as well as the increase in demand, there is also an increase in the complexity of electrical systems. It is more challenging than ever to ensure that everybody working in the industry, both old and new, are ready for what may face them out there in the real world.

This is the case of Colin…

The set-up

Colin is here to change a light fitting. He has recently qualified as an electrician. He remembers his safe isolation procedure training and carries out the following sequence of operations and observations:

- Turns the light fitting on. He observes the light fitting operating with the switch.

- Turns off the circuit-breaker (CB). He observes the light fitting go out.

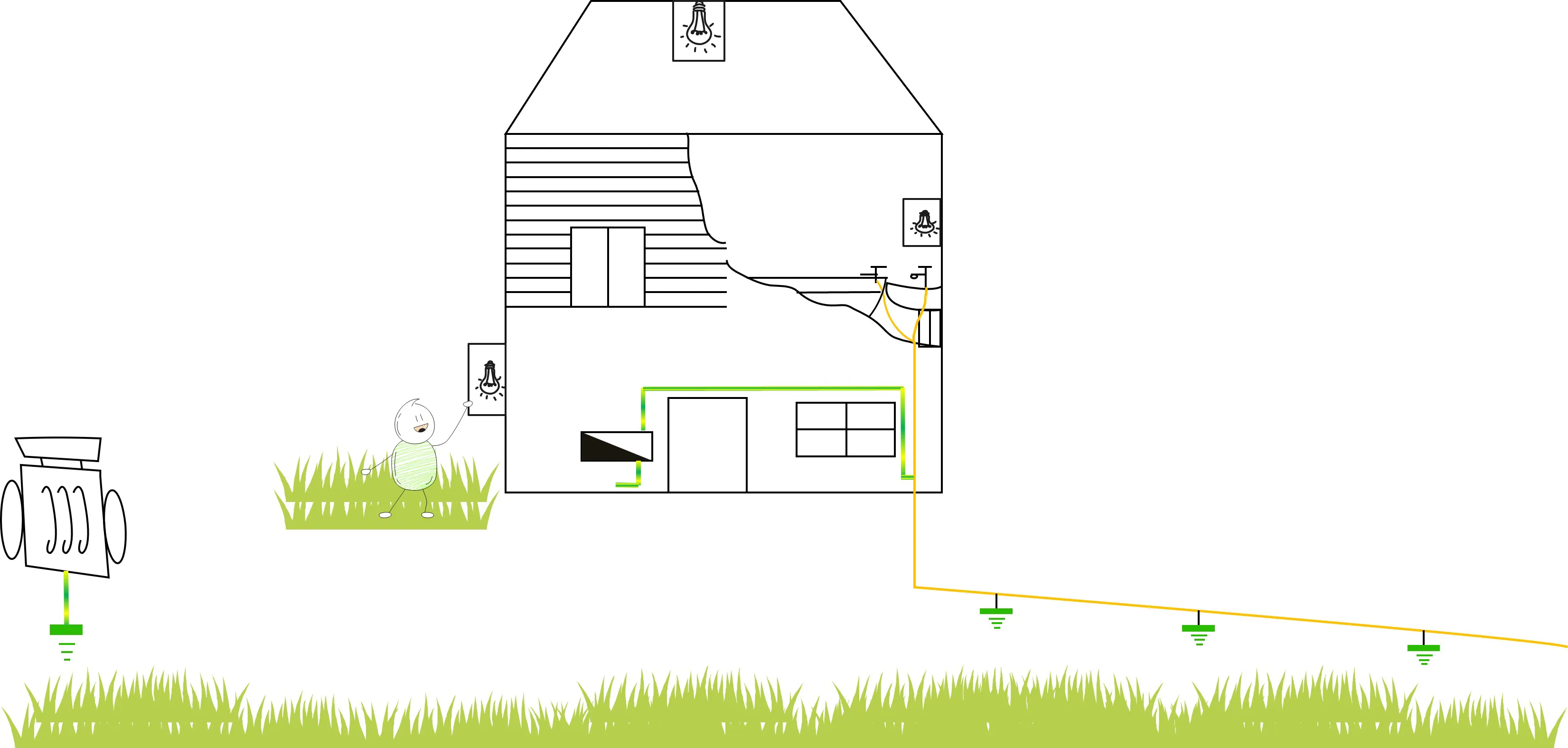

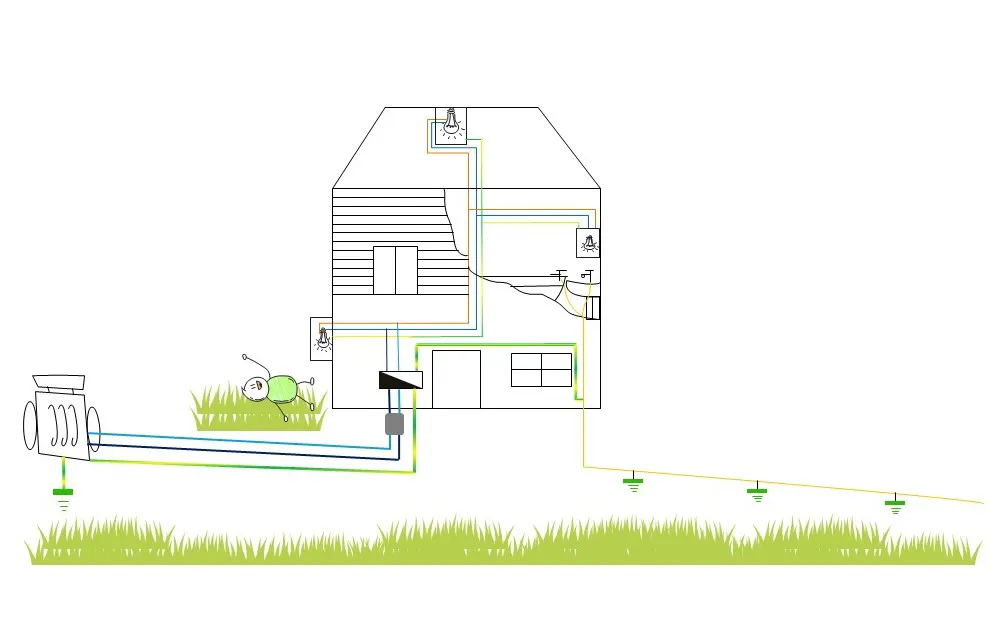

- Locks off the CB and attaches his warning notice. The system is 100 A single-phase TN-S earthing arrangement, so he is happy with single-pole isolation.

- Checks his proving unit and voltage indicator are functioning. All ok.

- Carefully removes the light fitting’s cover and tests between line-earth, neutral-earth and line-neutral. Records 0 volts on every test.

- Rechecks his voltage indicator with the proving unit. All ok.

Now ask yourself whether he is safe to work?

If you answered yes, then you need to keep reading.

The answer was no. Unfortunately, Colin received a shock which was surprising to him as he was certain he did everything to the procedure.

So, what went wrong?

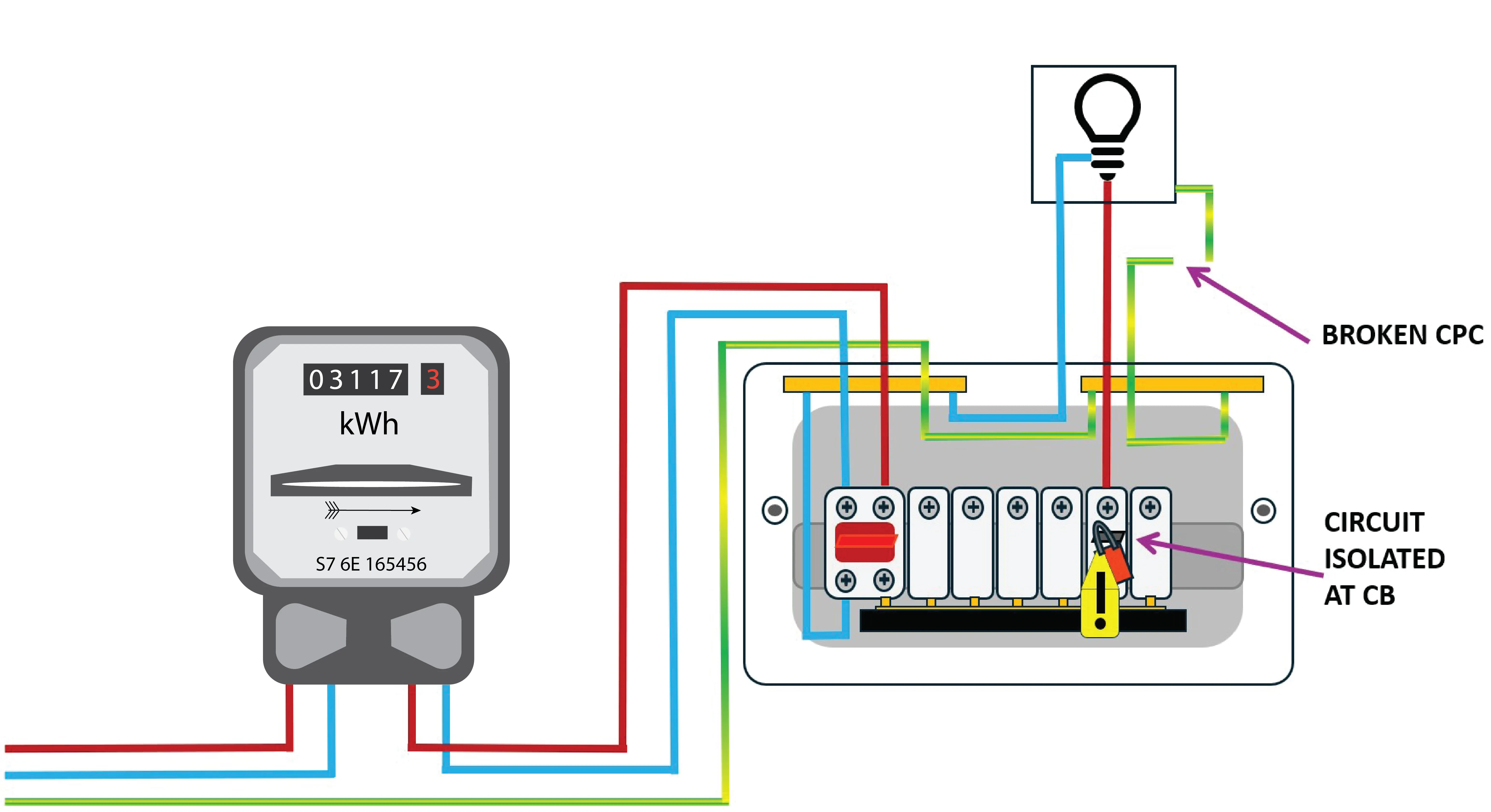

Unfortunately for Colin, the supply tails had been reversed by a recent replacement of the property’s energy meter and, compounding to that issue, the circuit protective conductor (cpc) at the light fitting did not have continuity back to the main earthing terminal (MET) as illustrated below.

This would mean that when he was at the light fitting, the neutral conductor was now his line conductor. There were no return paths for his voltage indicator to detect a potential difference. The CB was locked off in the open position and there was no continuity on the cpc. As a result of this, he was unable to detect the voltage present at the neutral terminal which gave him the shock of 230 V.

What could be done differently?

It is only possible to decide on a safe working procedure for a job if you are aware that these situations occur.

Regulation 132.16 of BS 7671:2018+A2:2022+A3:2024 requires electricians to ascertain that certain aspects of the installation are adequate before any additions or alterations take place, such as, the rating and condition of existing equipment, including that of the distributor, and earthing and bonding arrangements.

Applying these checks before starting work is logical and, in this case, could have highlighted an issue with the distributor’s equipment and supplier’s connections.

Regulation 134.2.1 of BS 7671:2018+A2:2022+A3:2024 also states that:

“During erection and on completion of an installation or an addition or alteration to an installation, and before it is put into service, appropriate inspection and testing shall be carried out by one or more skilled persons competent to verify that the requirements of BS 7671 have been met.

Appropriate certification shall be issued in accordance with Chapter 64.”

An earth fault loop impedance test at the light fitting could be deemed a suitable test to perform in this case (safely of course!). Confirming the circuit before swapping the light fitting is a logical option because it could help highlight an issue. In this situation, it would have highlighted there was a connection issue at the terminals and could have led Colin to a different approach.

Visual inspection

Our eyes tell us a lot about an installation; a visual inspection should always be part of any safe working procedure to keep an eye out for anything out of the ordinary. It may have highlighted reverse polarity at the meter however, if the colours were correct at the meter but terminated incorrectly inside the consumer unit (CU), then this inspection alone would not be a single solution.

Non-contact and single pole contact voltage indicators

These are becoming increasingly popular for many to carry out their work safely. Many electricians, along with distribution network operators (DNOs) and heating engineers, often utilize these types of voltage indicator as part of their procedures. Better awareness of safe isolation and other hazards such as protective earthed neutral (PEN) failures (see Wiring Matters article, March 2021, “Broken PEN”) have meant new methods have been introduced. Unlike GS38, approved two-pole voltage indicators will require batteries to function. Like all measuring and testing equipment, they will need to be treated carefully, away from impacts, and will need to be checked before and after use on a known source.

Figure 1 Non-contact voltage indicator. Reproduced by permission of Kewtech.

Figure 2 Single-pole voltage indicator. Reproduced by permission of Kewtech.

Some two-pole voltage indicators warn of the presence of a voltage with the contact of one pole connected. The unit relies on batteries to function and will also need to be checked before and after each use on a known source or proving unit.

GS38 Electrical test equipment for us on low voltage electrical systems is a guidance note from the Health and Safety Executive explaining safe methods of using test equipment on low voltage electrical systems.

Section 13 of GS38 suggests how to use non-contact and single-pole devices safely:

Double pole isolation?

Colin could have isolated the CU’s main switch. This would have isolated both poles and prevented the shock; however, he would still need an adequate procedure to identify and rectify the reverse polarity and cpc continuity issue before re-energizing.

It is important that any safe working method is thought-out thoroughly and always needs adapting to each individual environment an electrician is faced with.

What is competency?

Competency is a difficult thing to define in words (see Wiring Matters article, September 2024, “The ‘C’ word (competency in the electrical installation industry)”).

Some people describe competency as consisting of three things:

- Qualifications

- Integrity

- Experience.

Colin had the qualifications, and he certainly had the integrity, but was lacking a tiny bit of experience which, in this case, was relying on the procedure alone to tell him he was safe. This assumes everything is connected correctly which many electricians can verify is not always the case!

It's tempting to think that once someone is qualified they're ready for anything, although this is simply not true. Our electrical world has changed a lot in the last decade. The complexity of installations and systems is growing which means the possibility of errors is growing. As new technologies emerge, such as prosumers systems with multiple supplies bringing new problems and new hazards, cases such as Colin’s may increase. It is therefore important that we all start sharing these stories as much as possible to help each other, both old and new, coming to the electrical industry to understand these issues before they are encountered.

Please share these stories during toolbox talks and discuss safe working practices.

What would you do?

What would have been your safe method of working for this job Colin had? Let us know on the EngX thread below:

Safe isolation - are you sure you are safe?

Oh Colin? What happened to Colin?

Sadly, Colin never worked as an electrician again. This experience knocked his confidence to the extreme. He did receive some financial compensation, however it didn’t really help him after being off work for 6 months. This is another electrician lost to the industry which could have easily been avoided.

Special thanks to:

- Susannah Girt

- Mark Coles

- Michael Peace

- Joe Cannon

- Calum Mansell.