Removing the distributor's cut-out fuse

The topic of whether electricians are permitted to remove the distributor's cut-out fuse is one that causes debate within the industry.

A quick internet search on the subject leads to multiple perspectives and experiences from electricians across the UK.

This article looks to provide insight into the challenges, considerations and current options for electricians and clients looking to isolate domestic electrical installations for maintenance and installation works.

What is the issue?

Historically, only the Distribution Network Operator (DNO) who owns the cut-out fuse, the Meter Operator Agent (MOA) appointed by the electrical supplier for the property or, in some cases, those who are given express permission by the DNO, were permitted to withdraw and reinstate the cut-out fuse.

This has been a source of frustration for electricians and clients who require the cut-out fuse to be withdrawn for activities such as consumer unit replacements, and then reinstated upon completion.

The major push for electrical installations to encompass low carbon technologies (LCTs), such as heat pumps, solar photovoltaics (PV) and battery energy storage systems, has only exacerbated this issue, with long lead times, unexpected costs and a complicated application process cited as a negative experience for electricians and clients, particularly those responsible for large housing stocks, i.e., local authorities.

What are the responsibilities of the DNO?

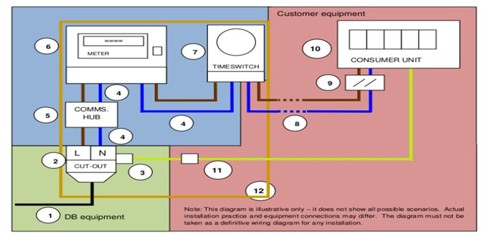

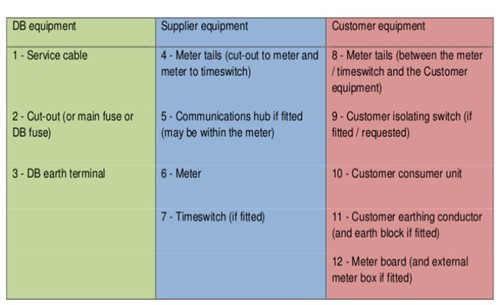

DNOs have a legal obligation to ensure the electrical equipment they own is safe, as per Section 24 of the Electricity Safety, Quality and Continuity Regulations (ESQCR) 2002 as amended1 and Section 25 of the ESQCR (Northern Ireland) 20122. The service cable, cut-out and distributor's earth terminal (where provided) all form part of this responsibility (see Figures 1 and 2).

In some cases, DNOs, such as Scottish and Southern Energy Networks (SSEN)3, permit electricians who are members of trade associations to break the security seal, remove the cut-out fuse and, following the works being undertaken, reinstate it.

The DNO would return afterwards to reseal it or provide the electrician with means to do so. However, this is not an option offered by all DNOs; therefore, electricians need to verify any specific procedures with the respective DNO before withdrawing a cut-out fuse.

At this point, it is important to highlight that this permission does not extend to the supplier’s equipment, such as the meter.

Figure 1 Diagram of equipment responsibility4. Image provided with kind permission of the Retail Energy Code.

Figure 2 Diagram of equipment responsibility descriptors5. Image provided with kind permission of the Retail Energy Code.

What does the law say?

Those performing electrical work, or supervising such work, must have sufficient technical knowledge, experience and practical skills to identify and manage risks associated with electrical work.

The privatization of the electrical supply industry in Great Britain was implemented under the Electricity Act 19896. The Act provides a legal framework for activities such as restoration of supply, while setting limitations on customers attempting to restore their supply without permission. In Northern Ireland, the electricity supply industry is governed by legislation such as the Energy (Northern Ireland) Order 20037.

In respect to the Electricity at Work Regulations (EAWR) 19898 or EAWR (Northern Ireland) 19919, the regulations are split into two categories.

1. Absolute: the requirement must be met regardless of cost or any other consideration

2. Reasonably practicable: to prevent harm to others, you should generally take all ‘reasonably practicable’ precautions. To do this, the degree of risk must be balanced with the steps required to control the actual risk in terms of money, time or trouble. If taking action is disproportionate to the level of risk, you are not required to do so.

In respect of removing the distributor’s cut-out fuse, four ‘absolute’ regulations stand out:

- Regulation 12: Means for cutting off the supply and for isolation

- Regulation 13: Precautions for work on equipment made dead

- Regulation 14: Work on or near live conductors

- Regulation 16: Persons to be competent to prevent danger and injury.

Isolation is essential for safety when working with or near electrical systems and protecting against electric shock, burns and other hazards. Therefore, the process of safe isolation and competency are intertwined; it is important that the person withdrawing the cut-out fuse is adequately trained, experienced and has the knowledge to ensure the safety of themselves and others.

What are the requirements of BS 7671?

Regulation 110.2 indent (i) of BS 7671:2018+A2:2022+A3:202410 excludes systems for the distribution of electricity to the public, apart from prosumer installations covered by Chapter 82. Therefore, as the cut-out fuse is the property of the distributor, BS 7671 does not refer to its withdrawal, with the exception of Regulation 714.537.2.1.202, which states approval is required prior to the withdrawal of a distributor's cut-out fuse for highway power supplies specific to outdoor lighting installations.

However, this was not always the case, as the 17th Edition of Requirements for Electrical Installations (the IET Wiring Regulations), BS 7671:2008+A3:201511, Regulation 537.1.3, referenced the withdrawal of a distributor's cut-out fuse within the standard (see below):

“537.1.3 Each installation shall have provision for disconnection from the supply.

"Where the distributor provides a means of disconnection complying with Chapter 53 at the origin of the installation and agrees that it may be used as the means of isolation for the part of the installation between the origin and the main linked switch or circuit-breaker required by Regulation 537.1.4, the requirement for isolation and switching of that part of the installation is satisfied.

"NOTE: A cut-out fuse may be withdrawn only by a person authorized to do so by the distributor.”

The standard also points to the responsibilities of those making additions or alterations to existing installations, to ascertain the rating and condition of any existing distributor's equipment, in Regulation 132.16 of BS 7671:2018+A2:2022+A3:2024.

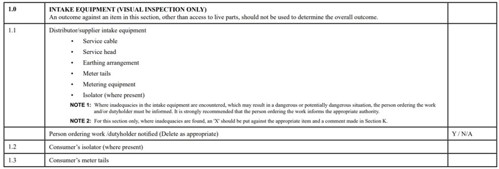

Additionally, inspectors undertaking the periodic inspection and testing of an electrical installation are required to carry out a visual inspection of the external condition of the distributor’s and supplier’s intake equipment. The model form in Appendix 6 of BS 7671:2018+A2:2022+A3:2024 for periodic inspection and testing refers to this (see Figure 3).

Figure 3 Intake equipment visual inspection12.

On the inspection schedule, item 1.1 is the only portion of the schedule which permits the inspector to record an X as opposed to a classification code. Recording an X does not affect the outcome of the report, although this is not the case where access to live parts has been found.

Where an inadequacy has been observed, the person ordering the report should be informed immediately and in writing. The person ordering the report should then notify the responsible party, i.e., the distributor or supplier.

It is common for electricians conducting activities, such as periodic inspection and testing, to identify cut-out fuses that have not been sealed.

Where the security seal is not in place or broken, the risk of exposure to live parts increases, as well as readily permitting unauthorized access for the purposes of meter tampering. Therefore, the person ordering the work should be notified and advised to contact the respective distributor.

Safe Isolation Providers (SIPs)

The clear need for more authorized persons capable of isolating the incoming electrical supply has been heightened, not only by the installation of LCTs but also the smart meter rollout. Therefore, the role of SIPs has been created by the Retail Energy Code (REC).

Organizations who are authorized as SIPs are permitted to withdraw and reinstate the cut-out fuse and, where required, adjust the terminals of meters and associated equipment, and terminate or replace the consumer meter tails on the meter.

This facilitates a single point of contact for customers to have electrical works completed without the involvement of the DNO or electrical supplier. SIPs can also install isolator switches at the same time to aid future necessity for isolation.

The role of SIPs is tightly regulated to alleviate concerns regarding meter tampering and provide traceability of those working on the intake equipment. Any organizations wishing to become a SIP must apply to do so and be an accredited MOA, recognized by the REC and an Electrical Metering Operative (EMO).

All works undertaken by SIPs are under the instruction of the person who owns the building, as laid out in the Distribution Connection and Use of System Agreement (DCUSA)13. A list of SIPs can be found on the REC Party Register14 via the REC Portal15.

Identifying issues with the distributor’s equipment?

The Consolidated Metering Code of Practice (CoMCoP)16 sets out the requirements for the installation, operation and maintenance of metering equipment. Whereas the Guidance for Service Termination Issue Reporting – A guide for MOCOPA on reporting and acting on Distribution Business asset condition issues (STIRG)17, utilizes an asset condition code for meter operatives to report defects and the asset condition of the distributor’s equipment to the DNO.

The codes are divided into three categories (see Table 1), similar to the classification codes stated within BS 7671, with example photographs provided along with useful guidance on next steps.

Table 1 Asset condition codes.

| Category | Action | Description |

| A | Emergency (immediate action required) | Distributor’s equipment poses a danger of death or injury to persons and/or damage to property. |

| B | Remedial work (attention required; the installation should be left in a safe condition) | An issue was identified with the condition of the distributor’s equipment that prevents work from being carried out (excluding a category A issue). |

| C | Asset condition (the DNO to be notified and appropriate action to be determined) | Distributor’s equipment is not to current standards (neither a category A issue nor a category B issue). |

While STIRG is aimed at meter operatives, it does provide useful insight into how distributors prioritize the maintenance activities of the equipment under inspection.

The current version is accessible to Metering Equipment Managers (MEMs) on the REC Portal, and previously, the document was produced under the Meter Operation Code of Practice Agreement (MOCoPA)18; however, since September 2021, REC has taken responsibility for STIRG.

Just because you can withdraw the cut-out fuse, should you?

As mentioned above, certain DNOs permit electricians who are members of trade associations to undertake the withdrawal of the cut-out fuse. While clearly this comes with benefits in terms of cost and efficiency, safe working practices should not be ignored.

DNOs have procedures in place for withdrawing and reinstating cut-out fuses, inclusive of where certain equipment or dangers are present. For example, SSEN requires its operatives to wear visors and electrically insulated gloves to withdraw and reinstate the cut-out fuse.

Where interference with the security seal has been identified, or signs of damage or distress are apparent, for example, overheating, this should be reported to the DNO, and withdrawal not undertaken.

Electricians should be aware that while permission may be granted by the DNO to remove the cut-out fuse, there are times when they will not be able to due to the potential dangers present on existing equipment, such as:

Surface voltage found on plastic cut-outs

Phenolic materials used in black plastic cut-outs (see Figure 4) between 1967 and 1992 have been known to become conductive and/or produce excessive heat. To create phenolic materials, phenolic resin was permeated into glass fibre, cotton or paper pulp, and bound via a combination of heat and pressure.

Overheating can cause materials to break down and leave behind an ash-like residue, which can conduct when wet. Conductive pathways on the surface of insulators, termed ‘tracking’, can lead to short-circuits and fires.

Figure 4 Cut-out made from phenolic material19. Image provided with kind permission of the Retail Energy Code.

The risk of surface voltages appearing on plastic cut-outs poses a risk of electric shock; therefore, STIRG provides meter operatives with specific guidance around initially testing via a direct contact voltage indicator, followed by supplementary tests with a two-pole voltage indicator where a sustained voltage is present (see Figure 5).

Figure 5 Testing the cut-out for the presence of surface for voltage20. Image provided with kind permission of the Retail Energy Code.

Cut-outs with a fused neutral

Generally installed prior to 1937, the ESQCR states cut-outs with fused neutrals (see Figure 6) must not be retained, and DNOs are required by the HSE to remove any within 28 days of identification. The danger is that if the neutral cut-out fuse ruptures, the line conductor remains energized.

Additionally, the loss of the neutral conductor can cause voltage fluctuations and damage to equipment.

Figure 6 Cut-out with a fused neutral21. Image provided with kind permission of the Retail Energy Code.

Asbestos containing materials (ACMs)

Older distributor’s equipment may contain asbestos, such as flash guards within rewireable fuse carriers (see Figure 7). When disturbed, these extremely friable, loosely bound materials permit the release of fibres into the atmosphere.

Figure 7 Fuse carriers containing ACMs22.

DNOs have specific procedures for the replacement of asbestos containing materials; therefore, the cut-out fuse should not be withdrawn, and the DNO should be notified.

Identification

The identification of the correct cut-out fuse is essential prior to withdrawal; for example, ground floor flats have been known to contain two cut-out fuses where the flat above is supplied at the same intake position (see Figure 8). This is not only a safety concern but may also have financial consequences due to loss of supply, so it is important to check.

Figure 8 Intake position with two cut-out fuses.

Summary

The removal of the cut-out fuse is an essential part in safely isolating an electrical installation to undertake the installation and maintenance of electrical equipment.

Electricians can be authorized by the DNO to remove and reinstate the cut-out fuse in certain circumstances; however, it should be remembered that it may not be practicable, or indeed safe, to do so in all cases.

The role of SIPs means there is another option for those requiring isolation of the electrical installation, and clients and electricians should strongly consider the benefits of using a SIP.

This includes formal accreditation, training for SIP operatives on the safe de-energization and re-energization of the electrical supply, and application of established safe working practices to minimize potential hazards and legal issues.

Regulation 16 of EAWR requires persons working on or near electrical systems to be competent. Continued professional development equips specialists with the knowledge and skills to adapt to changes in their industry and environment, ensuring they remain relevant and competitive.

Therefore, staying up to date with current industry guidance and best practices, and local DNO requirements and procedures, will assist electricians in visually inspecting and working safely when near distributor’s equipment.

Acknowledgements

- Andy Coole

- Bob Cairney

- Craig O’Neill

- Leon Markwell

- Mark Coles

- Max Parello

Further information

Energy Networks Association’s Distribution Network Operator Cut-out Types & Ratings Guidance.

References

- The Electrical Safety Quality and Continuity Regulations 2002, as amended, available at: https://www.legislation.gov.uk/uksi/2002/2665/regulation/24

- The Electrical Safety Quality and Continuity Regulations (Northern Ireland) 2012, available at https://www.legislation.gov.uk/nisr/2012/381/made

- Scottish and Southern Electricity Networks Procedure For The Removal And Replacement of Company Cut-Out Seals By Electrical Contractors, available at: https://www.ssen.co.uk/globalassets/library/connections---useful-documents/electrical-contractors/1-pr-net-cab-009-1.pdf

- Figure 1 taken from the Retail Energy Code Guidance for Service Termination Issue Reporting – A guide for Metering Equipment Managers on reporting and acting on Distribution Business asset condition issues, May 2025, Version 4.2.

- Figure 2 taken from the Retail Energy Code Guidance for Service Termination Issue Reporting – A guide for Metering Equipment Managers on reporting and acting on Distribution Business asset condition issues, May 2025, Version 4.2.

- Electricity Act 1989, available at: https://www.legislation.gov.uk/ukpga/1989/29/contents

- The Energy (Northern Ireland) Order 2003, available at: https://www.legislation.gov.uk/nisi/2003/419/contents

- The Electricity at Work Regulations 1989, available at: https://www.legislation.gov.uk/uksi/1989/635/contents

- The Electricity At Work Regulations (Northern Ireland) 1991, available at: https://www.legislation.gov.uk/nisr/1991/13/contents/made

- BS 7671:2018+A2:2022+A3:2024 Requirements for Electrical Installations, IET Wiring Regulations, Eighteenth Edition, available at: https://shop.theiet.org/requirements-for-electrical-installations-iet-wiring-regulations-eighteenth-edition-bs-7671-2018-a2-2022

- BS 7671:2008+A3:2015 Requirements for Electrical Installations. IET Wiring Regulations: https://knowledge.bsigroup.com/products/requirements-for-electrical-installations-iet-wiring-regulations

- Figure 3 taken from Appendix 6, Model forms for certification and reporting of BS 7671:2018+A2:2022+A3:2024 Requirements for Electrical Installations, IET Wiring Regulations, Eighteenth Edition

- The Distribution Connection and Use of System Agreement (DCUSA): https://www.dcusa.co.uk/

- Retail Energy Code Party Register via: https://recportal.co.uk/home

- Retail Energy Code Portal: https://recportal.co.uk/home

- Retail Energy Code Consolidated Metering Code of Practice (CoMCoP), available at: https://recportal.co.uk/documents/20121/0/CoMCoP+v2.2.pdf/ea4d1655-5b52-7958-1623-14078679ef96?t=1728916968550

- Retail Energy Code Guidance for Service Termination Issue Reporting – A guide for Metering Equipment Managers on reporting and acting on Distribution Business asset condition issues, May 2025, Version 4.2, available via: https://recportal.co.uk/home

- Retail Energy Code Meter Operation Code of Practice Agreement (MOCoPA), available at: https://www.retailenergycode.co.uk/extra/wp-content/uploads/2021/08/MOCoP-electricity-clean.pdf

- Figure 4 taken from the Retail Energy Code Guidance for Service Termination Issue Reporting – A guide for Metering Equipment Managers on reporting and acting on Distribution Business asset condition issues, May 2025, Version 4.2.

- Figure 5 taken from the Retail Energy Code Guidance for Service Termination Issue Reporting – A guide for Metering Equipment Managers on reporting and acting on Distribution Business asset condition issues, May 2025, Version 4.2.

- Figure 6 taken from the Retail Energy Code Guidance for Service Termination Issue Reporting – A guide for Metering Equipment Managers on reporting and acting on Distribution Business asset condition issues, May 2025, Version 4.2.

- Figure 7 taken from Asbestos guidance for electricians, Wiring Matters, Issue 81, July 2020, available at: https://electrical.theiet.org/wiring-matters/years/2020/81-july-2020/asbestos-guidance-for-electricians/