Minimizing the spread of fire and heat transmission

The requirements of BS 7671 for minimizing the risk of the spread of fire due to the wiring system are detailed within Section 527, specifically under:

- 527.1 Precautions within a fire-segregated compartment

- 527.2 Sealing of wiring system penetrations

These two sections consider the internal arrangements, as well as the external arrangements, to limit the risk of fire spread between sealed compartments within a premises where a wiring system passes through construction elements.

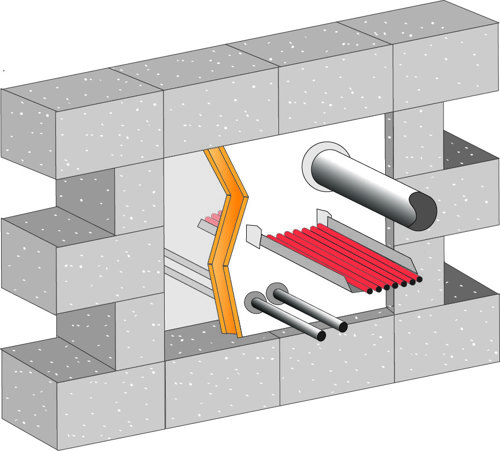

This article considers the basic requirements of passive fire protection, its certification and, more critically, the issue of whether a containment system (trunking) itself might pose a risk of thermal bridging and heat transmission between suitably sealed fire compartments against fire spread (see Figure 1).

Figure 1 Internal and external sealing at each floor level

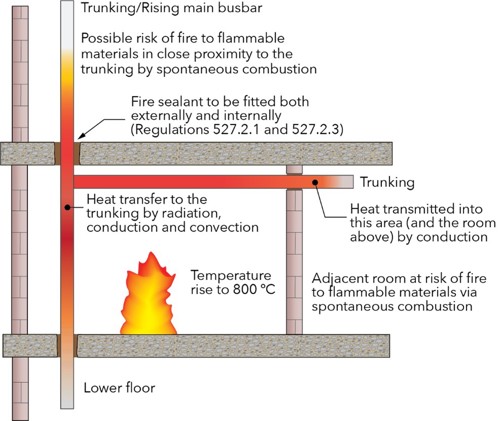

This latter aspect considers whether the heat transmitted through the wiring containment system (trunking or similar) will be sufficient to cause spontaneous combustion in a compartment ostensibly sealed from fire.

Passive fire protection

Passive fire protection (PFP) is a necessary feature used to limit the spread of fire between fire compartments[1]. The Association for Specialist Fire Protection (ASFP) has issued guidance in the form of the document, Ensuring Best Practice for Passive Fire Protection in Buildings.

This document states, “PFP is vital to the performance of a building structure in the event of fire. PFP is built into the structure to provide stability and into walls and floors to separate the building into areas of manageable risk.”

Section 527 of BS 7671 recognizes that wiring systems will need to make use of passive fire protection products. For example, Regulation 527.2.1 requires that where a wiring system passes through elements of a building construction (floors, walls, etc.), then the opening left behind shall be sealed “according to the degree of fire-resistance prescribed for the respective element of building construction before penetration” (see Figure 2). This requires, therefore, that where the construction element has, for example, a stated fire-resistance of 120 minutes, then any opening should be sealed to the same value.

Figure 2 Sealing of external penetration

Furthermore, Regulation 527.2.2 requires that wiring systems penetrating elements of building construction having specified fire-resistance shall be internally sealed to the same degree of fire resistance of the respective element. However, where the internal cross-sectional area does not exceed 710 mm2, the conduit system, cable ducting system and trunking system are classified as non-flame propagating, according to the relevant product standard (Regulation 527.2.3).

It is not important merely to seal; it is also important that the sealing arrangements are suitable for the wiring system and the cables which are part of the system (Regulation 527.2.4). Specifically, Regulation 527.2.4 requires that the sealing products:

- Are resistant to the products of combustion

- Have the same degree of protection against water penetration

- Are compatible with the material of the wiring system

- Permit thermal movement without reducing the seal quality

- Have adequate mechanical ability to withstand the stresses which may arise through damage to the support system due to fire.

Certification

Whilst there is no requirement within BS 7671 necessitating installed products to be certified by a third party, such as occurs when contractors are registered with organizations like NAPIT, NICEIC, SELECT, ECA, etc. third party certification is, however, an important feature of the industry and aids in supporting minimum levels of compliance with BS 7671.

Third party certification of the passive fire protection measures associated with the electrical installation is commonly necessary as part of a specification or due to insurance requirements.

However, such passive fire protection does not protect from heat transmitted by conduction through the containment system, as the containment system passes between two fire compartments.

Heat transfer

Metallic containment systems that are open to the temperature of a fire will transmit heat, primarily by means of conduction rather than radiation or convection.

The rate of heat transfer depends on several factors. These include, the type and thickness of metal, the temperature, specific heat capacity of the material, and the like.

Whilst this article does not go into detail on the calculation, it is important to recognize that where metallic containment systems are directly open to a fire, the temperature of the metallic containment system will rise for as long as the source of fire exists. It is worth noting that the temperature of a fire within a premises will vary according to a range of factors, but can be in the region of 600 – 1,000 °C.

Where a fire exists within a fire compartment for, say, 30 minutes, the rise in the temperature of the metallic containment system will rise to a value not dissimilar to the temperature of the fire itself (see Figure 3).

Where this is the case, the distance between the top of the containment system in the lower compartment and the temperature of the containment system in the compartment above will be little different. Indeed, it is likely that for a significant length, the temperature of the containment system will still be at a value sufficient to create the conditions for spontaneous combustion in neighbouring materials in proximity to the containment system.

Figure 3 Heat transmission through trunking. Courtesy of T.J. Bratley.

Conclusion

Where containment systems span between fire compartments, the designer and installer should not only carefully consider the passive fire protection issues, but they should also take care to limit thermal bridging, and the risk of fire spread by means of heat transmission through the metal of the containment itself.

Metallic containment systems enclosed in fire-resisting material, such as suitable plasterboard, will take significantly longer to rise to a temperature where heat transmission creates conditions for spontaneous combustion in those areas not affected by fire.

Where it is not possible to install containment systems in locations separate from fire compartments, metallic containment systems should be installed behind fire-resisting material to limit the risk of heat transmission.

[1] NOTE to Regulation 527.1.1 details a "fire-segregated compartment (fire compartment)" as, "…an enclosed space, which may be sub-divided, separated from adjoining spaces within a building by elements of construction having a specified fire resistance".