Part 1 - Exploring wiring systems for unearthed DC solar PV systems

The UK is committed to reaching net zero by 2050 and coupled with volatile energy prices, home and business owners are looking to invest in low carbon technology (LCT) with an aim to reduce energy costs and CO2 emissions.

Retrofitting direct current (DC) solar photovoltaic (PV) systems, especially cable routes, can be challenging to fit around existing services, be aesthetically pleasing and meet the requirements of BS 7671:2018+A2:2022+A3:2024.

In the UK, unearthed DC solar PV systems are adopted and use double or reinforced insulation as the protective measure. As such, DC solar cables designed to BS EN 50618 are already familiar to many, but new innovations are hitting the market, designed to aid designers, and these raise challenging questions in relation to safety.

This article will be formed of two parts. Part 1, published in the March 2025 issue of Wiring Matters, explores the possibility of using steel wire armoured (SWA) cable as an installation method for unearthed DC solar PV systems, for instance, permitting the connection of the PV modules to an inverter.

Part 2 will be published in a future issue of Wiring Matters and will consider whether or not the proliferation of safety measures built into modern inverters and associated electronic equipment might permit the use of new wiring systems and installation methods.

What protection method is used in unearthed DC solar PV systems?

The IET Code of Practice for Grid-connected Solar Photovoltaic Systems, 2nd Edition describes a PV module as a current limiting device with the short-circuit current of a PV array being not much greater than its operating current. Lack of significant fault current means a PV array requires a different approach when designing suitable fault protection.

In relation to the installation of cables, the current limiting nature of PV circuits means that additional protective measures are required to provide for fire and shock protection and Section 5.10.3 of the IET Code of Practice for Grid-connected Solar Photovoltaic Systems, 2nd Edition states:

All wiring systems shall have cables selected and erected to minimize the risk of earth faults and short circuits. All wiring systems shall be installed in accordance with Chapter 52 of BS 7671 to meet the requirements of Section 412 for double or reinforced insulation.

Why are DC solar PV systems unearthed?

Solar systems utilize inverters to convert the DC supply from the PV modules to alternating current (AC). Whilst inverters comprising isolating transformers exist and utilize an earthed DC system, in the UK, solar inverters are predominantly transformerless, using an unearthed DC system, and are preferred since they generally have higher efficiency and improved earth fault sensitivity.

What cables are commonly used to meet these requirements?

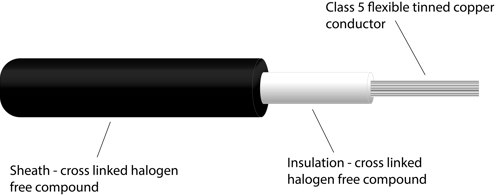

Insulated and sheathed cables, without metallic armouring or screens, such as those to BS EN 50618, are commonly used to meet the requirements of Section 412 of BS 7671:2018+A2:2022+A3:2024 for double or reinforced insulation, and cables installed within buildings may need to meet additional requirements, such as the use of cables of limited smoke production.

What installation methods are suitable?

The IET Code of Practice for Grid-connected Solar Photovoltaic Systems, 2nd Edition recommends that the cables shall not be directly buried in walls or otherwise directly encased in the fabric of the building, and where burial in walls cannot be avoided, they should be suitably protected from mechanical damage and a plan showing cable locations shall be provided.

It further recommends that solar PV DC cables buried in the ground shall be buried at a suitable depth and be protected against mechanical damage and impact in accordance with Regulation 522.8.10 of BS 7671:2018+A2:2022+A3:2024, by installation within an underground conduit or duct meeting the classification of N750 according to BS EN 61386-24:2010 Conduit systems for cable management - Particular requirements. Conduit systems buried underground (incorporating corrigendum November 2010). Additional measures are to be taken to limit access to rodents, rabbits, etc. at the open ends of the conduit as they enter/leave the ground, by the use of suitable filling materials meeting the requirements of the manufacturers of the conduit or duct and the cables installed within it.

It is also important to ensure that ducts are sealed with waterproof fillers where required, since ducting can fill with water and cables left lying in water may absorb moisture into the sheath and insulation over time (see Figure 1).

Figure 1 Examples of sealing ducts. Photographs reproduced by permission of AC Cable Solutions showing Duct Seal LG Cable Duct Sealing System.

Regulation 712.521.101 of BS 7671:2018+A2:2022+A3:2024 also states:

Cables on the DC side shall be selected and erected so as to minimize the risk of earth faults and short-circuits. This shall be achieved by using:

(i) single-core cables having a non-metallic sheath, or

(ii) insulated (single-core) conductors installed in individually insulated conduit or trunking. Cable(s) shall not be placed directly on the surface of the roof.

Other types of wiring system providing an equivalent degree of safety are not precluded. NOTE: BS EN 50618 describes cables intended for use at the direct current (DC) side of photovoltaic systems.

Why is protection by SELV, PELV or double or reinforced insulation required on the unearthed DC side of solar PV systems (BS 7671:2018+A2:2022+A3:2024, Regulation 712.410.102)?

There are, in fact, three things to consider in understanding why wiring systems (and other equipment) on the DC side are required to meet either the requirements for double or reinforced insulation, or alternatively, the requirements for separated extra-low voltage (SELV) or protective extra-low voltage (PELV):

- Reducing the risk of short-circuits leading to arcs, sparks and hence, fire, even if there is no overcurrent. Regardless of whether the inverter has separation between AC and DC sides, it helps prevent shorts between positive and negative within individual strings (overcurrent protection is usually only provided in multiple strings). This helps reduce risks of arcing and fire. The inverter may detect the condition and shut down, but unless there are DC power optimizers that also operate, the panels will continue to generate and feed any short-circuit fault.

- Protection against electric shock from the DC source, particularly where the nominal voltage on the DC side exceeds the relevant limits for SELV and PELV. In addition, where the inverter does not have protective separation between AC and DC sides, the conditions for SELV or PELV cannot be met. Electrical equipment on the DC side should be considered energized, even when the inverter is disconnected from the DC and/or AC sides (see Regulation 712.410.101 BS 7671:2018+A2:2022+A3:2024).

- Protection against faults that might cause the presence of AC on the DC side, and against contact with AC voltages to Earth, in systems with inverters not having separation between AC and DC sides.

Why might a designer wish to use SWA cable for unearthed DC solar PV connections?

SWA cable is used in AC systems where there is an increased risk of mechanical damage. The steel wire and the heavy-duty outer sheathing provides mechanical protection from minor abrasion and impact that might arise in environments such as being buried direct in the ground or where it may suffer from impact damage. The armouring does not protect against severe mechanical damage caused by puncturing or cutting through the steel, but it may provide protection from electric shock, since the armour is required to be earthed by Regulation 522.8.10 of BS 7671:2018+A2:2022+A3:2024. The protective measure used in this scenario is automatic disconnection of supply (ADS). For example, if a metal spade is driven through a buried SWA cable, current will flow through a live conductor, through the metal spade and back along the steel wire, causing disconnection by a protective device.

Designers of unearthed DC solar PV systems may have to consider where there is a risk of mechanical damage to a string cable, for example, cables connecting ground mounted arrays may be buried. As such, an installer may opt for using SWA cable as a possible design solution, however, there are further considerations which need to be taken into account before such a decision can be made.

Does SWA cable meet with the requirements of the protection method double or reinforced insulation?

In the UK, Regulation 712.312.2 of BS 7671:2018+A2:2022+A3:2024, does not permit the earthing of one of the live conductors of the DC side unless there is at least simple separation between the AC and DC side. As DC conductors within solar PV systems are typically unearthed, BS 7671:2018+A2:2022+A3:2024 denotes the protection method under Regulation 712.410.102 stating:

On the DC side, one of the following protective measures shall be applied:

(i) double or reinforced insulation (Section 412)

(ii) extra-low voltage (SELV or PELV) (Section 414)

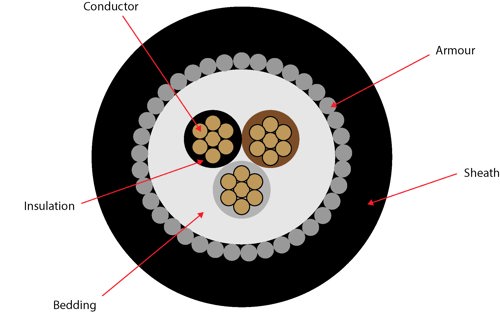

In the case of SWA cable manufactured to BS 5467, BS 6724 or BS 7846, these do not meet the requirements of indent (i) above, since the single cores are not double insulated from each other. The insulated cores lay next to each other and additionally, the filler material (bedding) does not have any insulation properties (See Figure 2).

Regulation 712.412.101 of BS 7671:2018+A2:2022+A3:2024 also states:

The electrical equipment, for example PV modules, wiring system (e.g. combiner box, cables) used on the DC side (up to the DC connection means of the PV inverter) shall be Class II or equivalent insulation. NOTE: For wiring systems, see Regulation 412.2.4.

Regulation 412.2.4.1 of BS 7671:2018+A2:2022+A3:2024 requires that in the case of wiring systems meeting the requirements of Regulation Group 412.2 relating to the requirements for basic protection and fault protection, where the protective measure of double or reinforced insulation is used, the mechanical protection is provided by the non-metallic sheath of the cable or non-metallic trunking or ducting. Users of the Standard may take from this the important point that it is best to avoid bringing unearthed DC wiring systems into close proximity to metal work that may become live due to a fault.

(Note: cables are often incorrectly referred to as double insulated, rather than insulated and sheathed. The reasoning is a wiring system is not classed as ‘equipment’, however, a wiring system which is insulated and sheathed is deemed to meet the requirements of 412.2. (See Wiring Matters Issue 75, May 2019, Mythbusters #4.)

Figure 2 Steel wire armour and solar cable.

Can I use an insulated and sheathed cable comprising a steel wire armour outer?

Where a manufacturer produces an SWA cable that replaces the single insulated conductors with insulated and sheathed cores, surrounded by steel wire armour and exterior sheath, whilst such a cable might have elements constructed in accordance with a relevant British or Harmonized Standard, the armoured ‘part’ of the cable would mean the final cable assembly is non-standard. If a designer selected such a cable, this would be a departure from BS 7671:2018+A2:2022+A3:2024 and they would need to state the design as being no less safe, despite its use in accordance with Regulation 133.1.3 of BS 7671:2018+A2:2022+A3:2024.

What design considerations must I address if I wish to use insulated and sheathed cable comprising a steel wire armour outer direct in the ground?

Regulation 522.8.10 of BS 7671:2018+A2:2022+A3:2024 states that:

Except where installed in a conduit or duct which provides equivalent protection against mechanical damage, a cable buried in the ground shall incorporate an earthed armour or metal sheath or both, suitable for use as a protective conductor.

Thus, the use of insulated and sheathed cables with an SWA exterior would require the armour to be earthed via one or more protective conductors when buried direct in the ground. Nevertheless, with unearthed DC solar PV systems, this would not be possible and any attempt to earth the armouring, either on the AC or the DC side, would not result in earthed armouring and may cause unintended consequences and introduce additional hazards. Regulation 522.8.10 of BS 7671:2018+A2:2022+A3:2024 would therefore require a suitable duct to be used, negating the need for armouring in the first place.

What if I choose to depart from BS 7671:2018+A2:2022+A3:2024?

Regulation 21 and 22 of The Electrical Safety, Quality and Continuity Regulations 2002 (ESQCR) specifically state that installations operating as a switched alternative in parallel to a distributor’s network must fully comply with British Standard requirements (i.e. BS 7671). The use of a cable buried direct in the ground without an earthed metal sheath or armour does not meet the requirements and is therefore not permitted.

Installers of unearthed DC solar PV systems should adhere to the Energy Networks Association (ENA) engineering documents relating to connection procedures. For systems where micro-generating plant with an aggregate registered capacity of 16 A (3.68 kW) per phase, or less, are installed, this would be Engineering Recommendation G98 Issue 1 Amendment 6 September 2021. For systems where generation is in excess of 16 A (3.68kW) per phase installers, this would be Engineering Recommendation G99 Issue 1 – Amendment 10, 4 March 2024. Both of these Recommendations require compliance with BS 7671.

Can I use insulated and sheathed cable with an SWA exterior in ducting or other locations?

The requirements of Regulation 712.521.101 of BS 7671:2018+A2:2022+A3:2024 state that:

Cables on the DC side shall be selected and erected so as to minimize the risk of earth faults.

The use of insulated and sheathed cables with an SWA exterior will clearly have been chosen as a consequence of a designer being concerned that mechanical damage could occur and thus, steel wire could become live in the event of damage which could turn an unearthed DC system into an earthed DC system and introduce other potential hazards (for example, no method of providing ADS).

Regardless, Regulation 712.312.2 of BS 7671:2018+A2:2022+A3:2024 states:

Earthing of one of the live conductors of the DC side is permitted, if there is at least simple separation between the AC side and the DC side;

In the case of a transformerless inverter, this is not permitted. The fundamental rule for protection against electric shock is a requirement in Section 410 of BS 7671:2018+A2:2022+A3:2024:

The fundamental rule of protection against electric shock, according to BS EN 61140, is that hazardous-live-parts shall not be accessible and accessible conductive parts shall not be hazardous-live, both under normal conditions and under single fault conditions.

This might lead a designer to assume that insulated and sheathed cables with an SWA exterior would be fine to use on unearthed DC solar PV systems because a single fault would only result in damage to the sheathing, but clearly there would be a risk that such damage would more than likely result in a fault to earth.

Given that solar PV cable is required to meet the requirements of the protective measure of double insulation, this regulation seems to suggest that installers should be wary of introducing a fault to metal work, even where two faults (damage to sheath and damage to insulation) would need to occur. Indeed, BS EN 61140 states:

If a single fault condition results in one or more other fault conditions, all are considered as one single fault condition.

With respect to wiring systems in general, BS 7671:2018+A2:2022+A3:2024 is clear with the requirements in Regulation 412.2.4.1:

Wiring systems installed in accordance with Chapter 52 are considered to meet the requirements of Regulation 412.2 if: (i) the rated voltage of the cable(s) is not less than the nominal voltage of the system and at least 300/500 V, and (ii) adequate mechanical protection of the basic insulation is provided by one or more of the following: (a) The non-metallic sheath of the cable (b) Non-metallic trunking or ducting complying with the BS EN 50085 series of standards, or non-metallic conduit complying with the BS EN 61386 series of standards.

In the case that insulated and sheathed cables with an SWA exterior are installed using any other method of installation other than buried direct, whilst not specifically prohibited, this regulation implies that mechanical protection should be provided by non-metallic trunking or ducting and the introduction of metal armouring is therefore undesirable.

Summary

Traditional wiring systems, such as suitably impact rated insulated ducting to N750 and insulated and sheathed cable, meet the requirements of BS 7671 and provide adequate safety to human beings and livestock.

The use of single insulated SWA cable for unearthed solar DC cabling is not permitted by BS 7671 as it does not provide double insulation between the string conductors.

Insulated and sheathed cables with an SWA exterior may arguably be permitted for unearthed solar PV cabling where it is not directly buried in the ground. Where it is buried direct in the ground, the cable must be earthed in accordance with Regulation 522.8.10 which is not possible in an unearthed system and is therefore not permitted.

Other cables, such as insulated and sheathed cables wrapped in a “tough sheath”, could be used where there is a concern about cables being damaged as they are drawn into ducting or conduit.

Acknowledgements

- Brian Abbott

- Craig O’Neill

- Darren Crannis

- Graham Kenyon

- Jason Kirrage

- Joe Cannon

- Leon Markwell

- Mark Coles

- Michael Peace

References

Buried conduits and ducts

Mythbusters #4 Double insulated cables